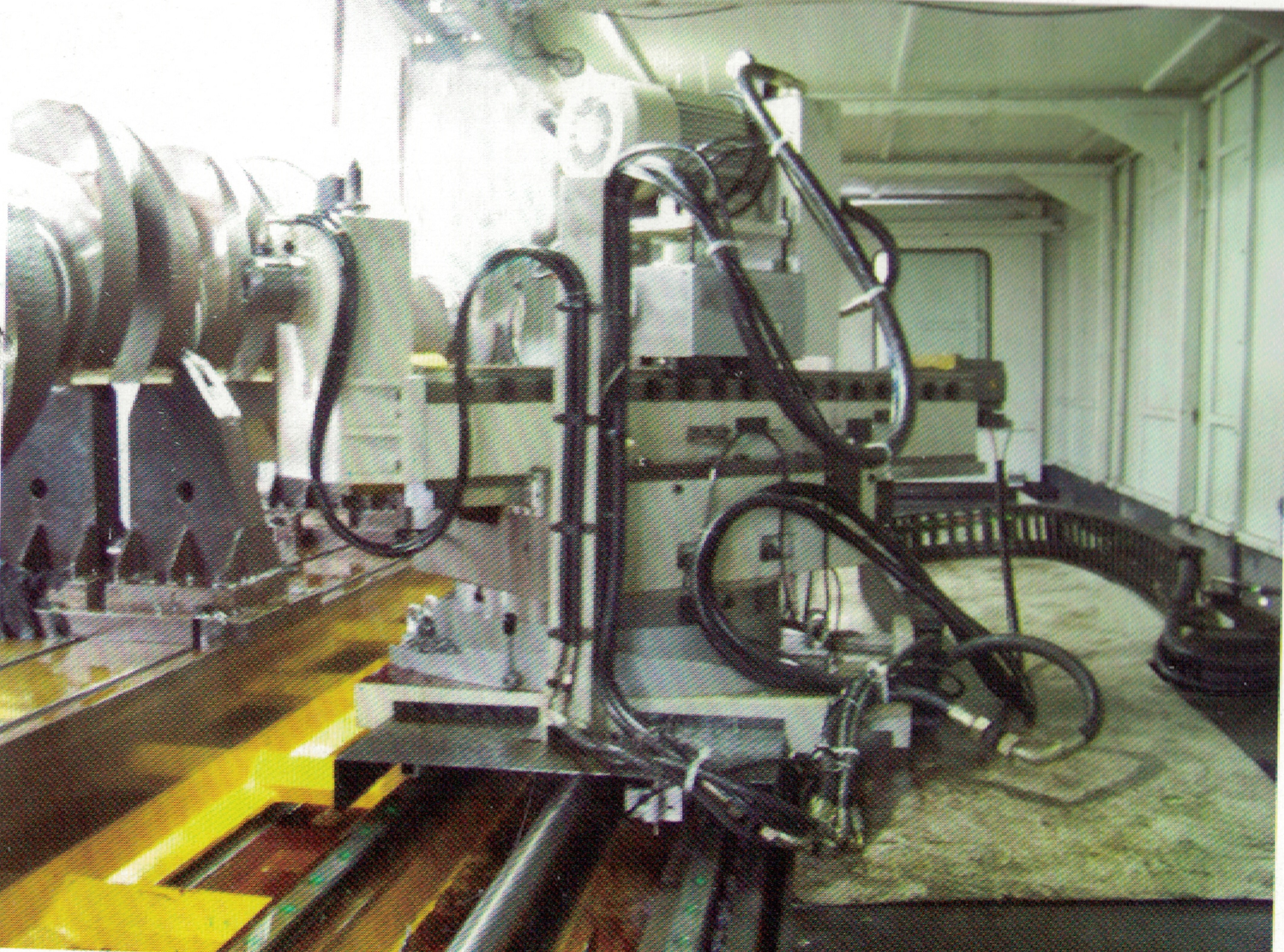

ZQK42 series CNC deep hole drilling machine for crankshaft, CNC 7-axis oil hole of crankshaft drilling machine

This equipment is a specialized machine for processing deep holes in the crankshaft, using the external chip removal method (gun drill) to process the deep holes on the crankshaft. The axial movement of the rotating power head and the processing of drilling depth are all using CNC methods, while the rotation of the crankshaft and the angle rotation of the power head can be by servo driving methods. During processing, the workpiece is through the A-axis angular rotation servo axis to locate and fix the position, while various auxiliary clamping and positioning devices on the worktable are adjusted. The power head and cutting tool are through the B-axis servo to rotate to the appropriate angle and to be fixed, and then to be moved to the appropriate position under the drive of X-axis (adjust the tool in the workpiece axial position) CNC system. The power head cutting tool rotates and feeds to start processing hole. After the completion of machining one hole, the power head moves axially to the appropriate position, and at the same time, the crankshaft rotates to the position of the next hole to be machined through A axis CNC servo indexing head, starting the next hole machining (if the drilling angle changes, the B axis servo rotates to the appropriate angle and then fix the position).

Main technical parameter

| Main technical parameter |

ZQK42 series (three coordinates or two coordinates) |

||

|

ZQK4202 |

ZQK4203 |

ZQK4204 |

|

| Machining diameter range | Φ3-Φ20mm | Φ4-Φ30mm | Φ8-Φ40mm |

| Max. drilling depth | 300 mm | 600mm | 1000mm |

| Rotation speed of power head | 800-7000r/min | 800-6000r/min | 500-4000r/min |

| Feed speed (mm/min) | 5-500 | 10-500 | 10-800 |

| Rapid feed speed (mm/min) | 3000 | 3000 | 3000 |

| Capacity of oil tank (L) | 1000 | 1500 | 1500 |

| Number of spindles | 1,2,3,4 | 1 or 2 | 1 or 2 |

| CNC system | optional | Optional | Optional |

| Lift travel of lifting table (Y axis) | 3000mm | 1000mm | 1000 (or customized) |

| Max.travel of worktable (X axis) | 650mm/800mm | 1000/1500/2000(mm) | 1000/1500/2000(mm)Or customized |

| Size of worktable | Matched | Matched | Matched |

| Pressure of coolant | 1-10MPa | 1-10MPa | 1-6MPa |

| Flow of coolant | 6-80L/min | 6-100L/min | 10-150L/min |

| General power of motors | 22/25 kW | Approx. 28KW | Approx. 32KW |

| X, Y, Z axis positioning accuracy | 0.05mm | 0.05mm | 0.05mm |

| X, Y, Z axis repeat positioning accuracy | 0.03mm | 0.03mm | 0.03mm |

| Remark: this product is a series of products that can be customized with various special requirements and shaped parts according to user needs | |||