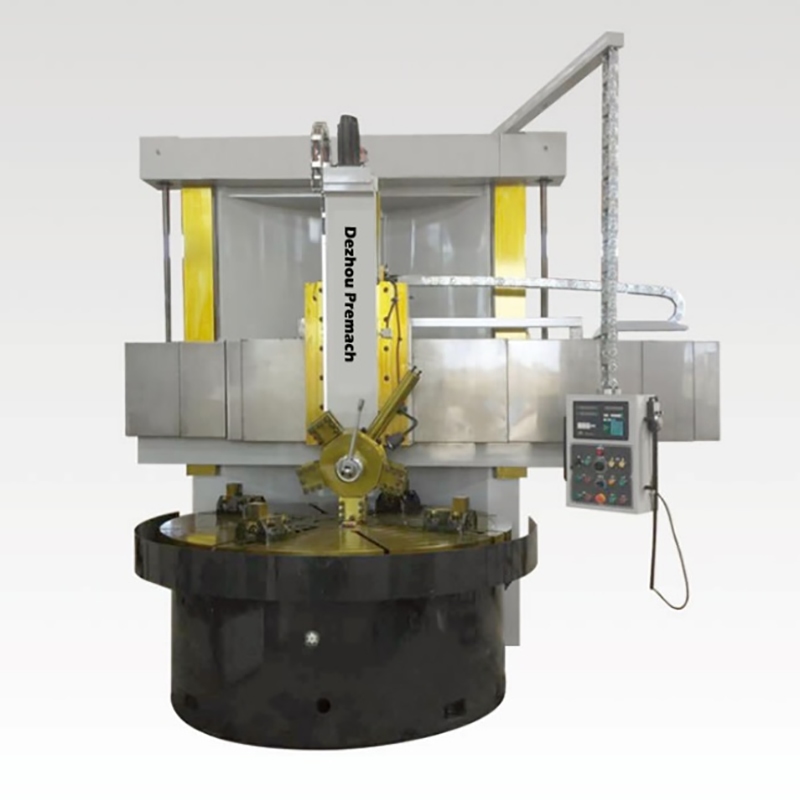

Trending Products Heavy Duty Lathe Machine - Vertical lathe C5112A series – Premach

Trending Products Heavy Duty Lathe Machine - Vertical lathe C5112A series – Premach Detail:

features of the machine

The machine tool is of single column structure. It is composed of crossbeam, workbench, crossbeam lifting mechanism, vertical tool rest, hydraulic device and electric control cabinet. We can also install side tool rest according to the customer’s requirement.

The features of this structure are as follows:

1. Worktable mechanism

The worktable mechanism is composed of worktable, worktable base and spindle device. The worktable has the functions of start, stop, jog and speed change. The worktable is used to bear the load in the vertical direction. The machine can work normally under the ambient temperature of 0-40 ℃.

2. Crossbeam mechanism

The crossbeam is placed in front of the column to make the crossbeam move vertically on the column. There is a lifting box on the upper part of the column, which is driven by an AC motor. The crossbeam moves vertically along the column guide way through worm pairs and lead screws. All large parts are made of high strength and low stress cast iron material HT250. After aging treatment, the stress is eliminated to ensure the accuracy of the machine tool, with sufficient pressure resistance and rigidity.

3. Vertical tool post

The vertical tool post is composed of crossbeam slide seat, rotary seat, pentagonal tool table and hydraulic mechanism. T-type ram, made of HT250, is used. After quenching and tempering treatment, the surface of the guide way is hardened after rough machining, and then refined by high-precision guide way grinder. It has the characteristics of high precision, good precision stability and no deformation. The ram pressing plate is a closed pressing plate, which increases the stability of its structure. The ram moves quickly. The tool rest ram is equipped with a hydraulic balance device to balance the weight of the ram and make the ram move smoothly.

4. Main transmission mechanism

The transmission of the main transmission mechanism of the machine tool adopts a 16 stage transmission, and the hydraulic cylinder is pushed by the hydraulic solenoid valve to achieve a 16 stage transmission. The material of the box is HT250, which is subject to two aging treatments, without deformation and good stability.

5. Side tool post

The side tool post is composed of a feed box, a side tool post box, a ram, etc. during operation, the feed box is used for speed change and gear rack transmission to complete feed processing and rapid movement.

6. Electrical system

The electrical control elements of the machine tool are installed in the power distribution cabinet, and all operating elements are centrally installed on the suspended button station.

7. Hydraulic station

The hydraulic station includes: the static pressure system of the worktable, the main transmission speed change system, the beam clamping system, and the hydraulic balance system of the vertical tool rest ram. The static pressure system of the worktable is supplied by the oil pump, which distributes the static pressure oil to each oil pool. The floating height of the worktable can be adjusted to 0.06-0.15mm.

Technical parameter

| specification | unit | C5112A | C5116A |

| Max. turning diameter | mm | 1250 | 1600 |

| Worktable diameter | mm | 1000 | 1400 |

| Max. workpiece weight | T | 3.2 | 5 |

| Range of worktable speed | r/min | 6.3-200 | 5-160 |

| step | 16 | 16 | |

| Motor power | KW | 22 | 30 |

| Max. height of workpiece | mm | 1000 | 1200/1400 |

| Stoke of vertical toolpost (level) | mm | 700 | 915 |

| Stoke of vertical toolpost (vertical) | mm | 650 | 800 |

| Stoke of vertical toolpost (level) | mm | 500 | 650 |

| Stoke of vertical toolpost (vertical) | mm | 900 | 1000 |

| Weight of machine (approx.) | T | 9.5 | 12.5 |

| Overall dimension | mm | 2277*2540*3403 | 2662*2800*3550 |

| specification | unit | C5120A | C5132A | C5126A | C5132A |

| Max. turning diameter | mm | 2000 | 2300 | 2600 | 3200 |

| Worktable diameter | mm | 1800 | 2000 | 2000/2250 | 2500 |

| Max. workpiece weight | T | 8 | 8 | 8-10 | 12 |

| Range of worktable speed | r/min | 4-125 | 3.2-100 | 2.5-80 | 2-63 |

| step | 16 | 16 | 16 | 16 | |

| Motor power | KW | 30/37 | 30/37 | 37/45 | 45/55 |

| Max. height of workpiece | mm | 1250/1400/1600 | 1250/1400/1600 | 1350/1500/1800 | 1400/1600/1800 |

| Stoke of vertical toolpost (level) | mm | 1110 | 1210 | 1265 | 1800 |

| Stoke of vertical toolpost (vertical) | mm | 800 | 900 | 800 | 1000 |

| Stoke of vertical toolpost (level) | mm | 630 | 630 | 780 | 630 |

| Stoke of vertical toolpost (vertical) | mm | 1110 | 1150 | 900 | 1150 |

| Weight of machine (approx.) | T | 17.5 | 19.5 | 19-25 | 28-32 |

| Overall dimension | mm | 3235*3240*3910 | 3360*3010*3900 | 3360*3010*3900 | 3250*4100*3800/4000 |

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the toughness by quality. Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for Trending Products Heavy Duty Lathe Machine - Vertical lathe C5112A series – Premach , The product will supply to all over the world, such as: Jakarta, Israel, Italy, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!