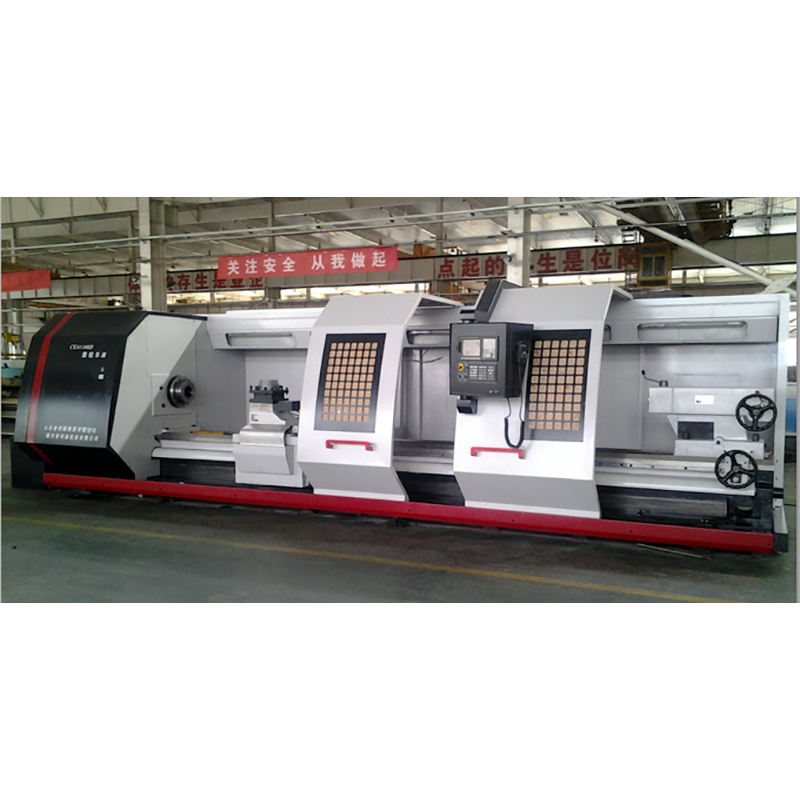

Reasonable Price Vtl Turning - CNC horizonta lathe machine CK6163C series – Premach

Reasonable Price Vtl Turning - CNC horizonta lathe machine CK6163C series – Premach Detail:

Property of the lathe

This series CNC lathe can be mated with FANUC, SIEMENS or other Chinese CNC system, with programmable control and CRT display. AC servo motor is used for Z axis and X axis feeding, pulse encoder is used for feedback. The bed guide way is made of high-strength resin iron casting and ground after ultrasonic frequency quenching. The guide way carriage is pasted with plastic so

as to reduce friction.

The contacting area between the headstock and the machine bed is large. After scraping and grinding, the ability to bear the cutting force generated of heavy cutting of the workpiece is furtherenhanced, and the stability of the machine is also strengthened. The main motor of the machine can be chosen a high-power frequency converting motor and adopts three supports structure with strong rigidity. After the simplificationof the transmission at the head of the machine tool, it can provide enough torque at low rotation speed to cut large and heavy workpieces. Especially when

machining workpiece blanks, it ensures the normal operation of the machine tool with large cutting amount. When shifting to low gear the main motor can work at full power, which provides the necessary premise for fast machining.

This machine has a wide cutting range, can process outer circle, inner hole and end face. Grooving, machining taper surface, chamfering, conical or cylindrical thread and arc surface.

MAIN TECHNICAL

|

MODEL |

|||||

| ITEM | CK6163C | CK6180C | CK61100C | CK61120C | |

| Max. swing over bed | 630mm | 800mm | 1000mm | 1200mm | |

| Max. swing over cross slide | 315mm | 450mm | 650mm | 850mm | |

| Distance between centers |

700,1200,1700,2700,3700,4700,5700,8000,10000,12000mm |

||||

| Spindle hole |

105mm |

105mm or 130mm |

|||

| Max. moving distance of tool post |

|

||||

| longitudinal |

1000,1500,2000,3000,4000,5000,6000,8000,10000,12000mm |

||||

| transversal |

450mm |

||||

| Spindle speed (number) | 14-750rpm, 18 steps, or manual three gears, stepless speed | ||||

| Main motor power |

11KW, or frequency converting motor |

||||

| Rapid travel speed | |||||

| longitudinal |

6m/min |

||||

| transversal |

3m/min |

||||

| Feed resolution ratio | |||||

| longitudinal |

0.01mm |

||||

| transversal |

0.005mm |

||||

| Position number of tool post |

4, 6 or 8, optional |

||||

| Positioning accuracy | |||||

| longitudinal |

0.03/500mm 0.05/2000mm |

||||

| transversal |

0.02mm |

||||

| Repeat positioning accuracy |

|

||||

| longitudinal |

0.013/500mm 0.025/2000mm |

||||

| transversal |

0.01mm |

||||

| Repeat positioning accuracy of tool pot |

0.005mm |

||||

| Net weight |

|

||||

| Distance between centers:1000mm | 3500kg | 3800kg |

4000kg |

||

| 1500mm | 3800kg | 4300kg |

4500kg |

||

| Overall dimension (LxWxH) |

|

||||

| Distance between centers: 1500mm |

|

2950x1600x1950mm |

|

||

| 2000mm |

|

3452x1600x1950mm |

|||

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Reasonable Price Vtl Turning - CNC horizonta lathe machine CK6163C series – Premach , The product will supply to all over the world, such as: India, New Zealand, Manchester, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.