Quality Inspection for Xg40 High Precision Machine Mini Metal Lathe Slant Bed Lathe

To create more value for customers is our business philosophy; customer growing is our working chase for Quality Inspection for Xg40 High Precision Machine Mini Metal Lathe Slant Bed Lathe, Our really specialized process eliminates the component failure and offers our shoppers unvarying top quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

To create more value for customers is our business philosophy; customer growing is our working chase for China High Speed Lathe and CNC Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade goods in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We’ve been willing to cooperate with business friends from at home and abroad and create a great future together.

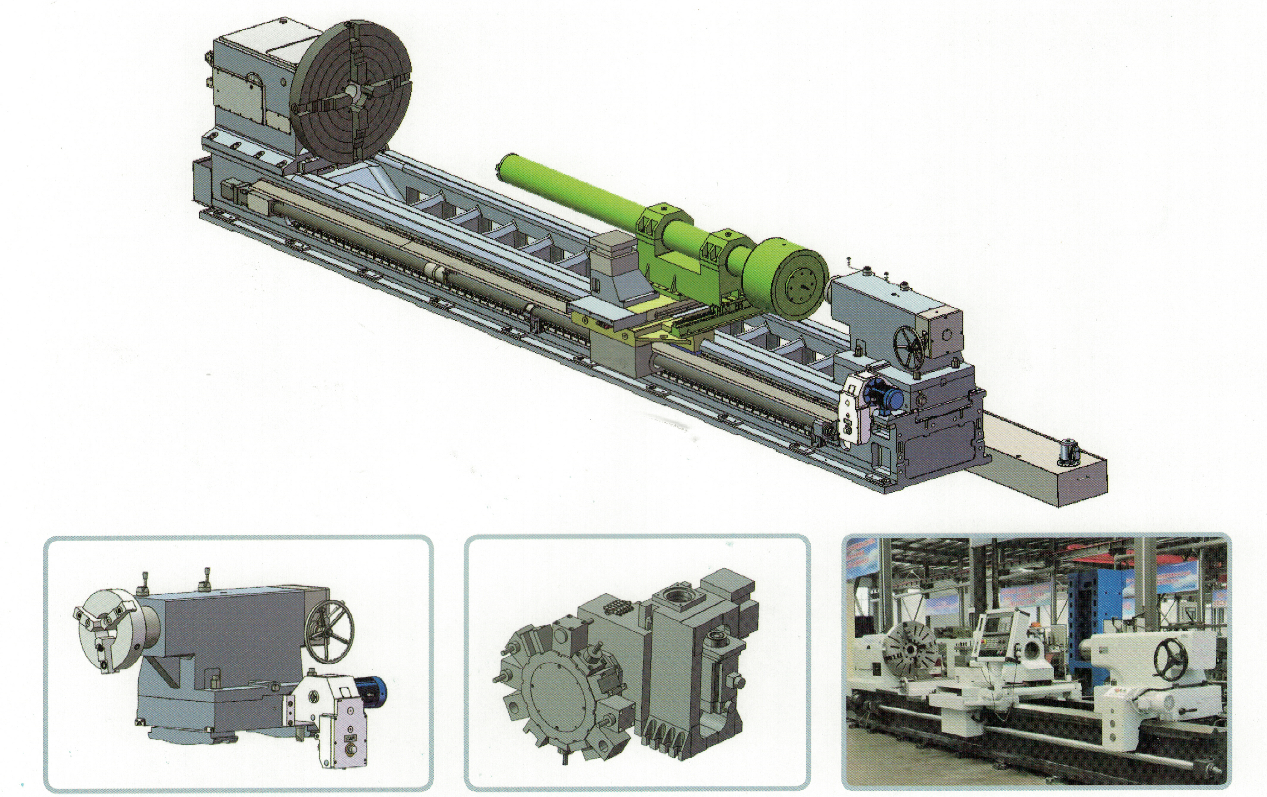

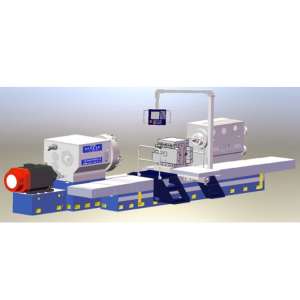

This machine is a multifunctional lathe developed by our company on the basis of a large flat-bed CNC horizontal lathe with boring function. The bed is optimized, the overall weight is increased, the carriage is lengthened, widened, and thickened, and a dedicated boring tool holder is supplied. It can cut the inner holes of parts, and the processing efficiency, accuracy, and rigidity are better than ordinary CNC lathes. Adopting a semi enclosed protective structure and equipped with Siemens systems. The main transmission of turning is automatic four speed continuously variable speed, with two linked control axes. The X and Z axes use ball screw pairs, AC servo motors, and precision reducers to achieve servo movement, semi closed loop control, and have good positioning accuracy and repeated positioning accuracy.

Product application areas:

1. Medium and large hydraulic cylinders

2. Full process machining of wind turbine spindles

3. The Drum in the Paper Industry

4. Wire rope drum of crane

5. Cathode rod drum

6. Centrifuge drum

7. Efficient turning of precious metals such as high-temperature alloys, titanium alloys, steel ingots, rollers, and laser cladding materials

8. Processing of thin-walled parts such as outer circle turning, inner hole boring, end face drilling, tapping, shaft surface drilling, milling, etc

Main technical parameter

|

Guide way width |

1100mm |

|||

|

Max. swing diameter over bed |

1320/1670/2070 |

|||

|

Max. workpiece length |

3000/4000/5000/6000/7000/8000/9000/10000/20000mm, the lathe over 10m is rack transmission |

|||

|

Workpiece weight between centers |

15T(pay attention to the speed limit for heavy part) |

|||

|

Max. swing diameter over carriage |

Φ900mm/1200mm/1600mm |

|||

|

spindle |

||||

|

Front bearing of spindle |

Φ200/220mm(optional) |

|||

|

Spindle speed |

||||

|

4 gears, stepless |

I gear |

II gear |

III gear |

IV gear |

|

Speed range |

5~40 r/min |

20~80r/min |

40~160r/min |

80~315 r/min |

|

Gear shift |

Hydraulic gear shift |

|||

|

Spindle bore diameter |

Φ130mm |

|||

|

Front end taper of spindle bore |

Metric 140# |

|||

|

Type of spindle end |

A2-15 |

|||

|

chuck |

Φ1000mm |

|||

|

Chuck type |

Manual four jaw chuck |

|||

|

Main motor |

||||

|

Main motor power |

30kW servo |

|||

|

Transmission type |

C type belt |

|||

|

Feed |

||||

|

X axis travel |

750/750/850/1050mm |

|||

|

Z axis travel(from chuck end to tailstock) |

2750/3750/4750/5750/6750/7750/8750/19750mm |

|||

|

X axis rapid travel speed |

4m/min |

|||

|

z axis rapid travel speed |

4m/min |

|||

|

Tool post |

||||

|

Vertical 4 position |

Electrical tool post |

|||

|

Type of tool post |

LD4B-C6100 |

|||

|

opposite side of tool post |

300×300mm, optional(380×380) |

|||

|

Tool shank section size |

45×45mm |

|||

|

Tailstock |

||||

|

Type of tailstock |

Manual tailstock |

|||

|

Mandrel diameter |

φ280mm |

|||

|

Mandrel travel |

300mm |

|||

|

Taper of mandrel |

Metric 80# |

|||

|

Moving type of tailstock |

Hanging/Motorized |

|||

|

Machining accuracy |

||||

|

Roundness of fine turning outer circle |

0.01mm |

|||

|

Consistency of precision machining of outer circles(on 300mm length) |

0.03mm |

|||

|

Flatness for fine turning flat(on diameter 300mm) |

0.025 concave |

|||

|

Roughness for find turning outer circle |

1.6μm |

|||

processing video please visit: https://youtu.be/Vj2U_kIEONQTo create more value for customers is our business philosophy; customer growing is our working chase for Quality Inspection for Xg40 High Precision Machine Mini Metal Lathe Slant Bed Lathe, Our really specialized process eliminates the component failure and offers our shoppers unvarying top quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

Quality Inspection for China High Speed Lathe and CNC Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade goods in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We’ve been willing to cooperate with business friends from at home and abroad and create a great future together.