Products

-

Three guide ways heavy duty horizontal CNC lathe C61200S series

The C61xxS series is an improved series of heavy-duty horizontal lathes with three guide ways developed by our company based on our long-term experience in producing horizontal lathes and adopting internationally advanced design means and manufacturing technology. It is a well-designed product integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool products integrating multiple categories of precision manufacturing technology. The structure and performance of the machine tool are applicable. The machine tool has the characteristics of high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

-

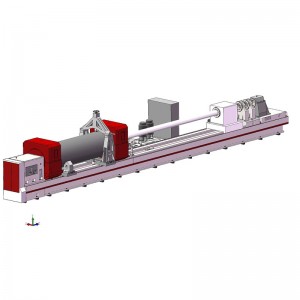

TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine

The machine is a kind of high efficiency, high precision, high automation deep hole boring and honing compound equipment. It is used for boring and honing cylindrical workpiece.

In the process of machining, the workpiece rotates and the cutting tool does not rotate.

The cutting oil for boring and honing is different. The machine tool is equipped with two sets of oil supply system and oil tank. When the two processing methods are converted, they need to be switched to their respective oil circuits.

Boring and honing share the same cutting tool tube.

-

Heavy duty horizontal CNC lathe CG series

This series of heavy-duty horizontal lathes is a kind of well-designed and multi-disciplinary lathe integrating electrical, automatic control, hydraulic control and modern mechanical design, which is based on the our company’s long-term experience in the production of horizontal lathe. has absorbed the advanced technology of the international era, adopted the international advanced design means and manufacturing technology, such as three-dimensional modeling, simulation design, finite element analysis, etc. Mechatronic machine tool products integrating multiple categories of precision manufacturing technology.

-

ZK2302/ZK2303 Series 3D CNC Deep Hole Drilling Machine

This machine is a deep hole processing equipment for drilling holes with 3D workpiece. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy can reach IT7-IT10, the surface roughness can reach Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

All our products have to go through three separate checks throughout the whole manufacturing process: materal, every part for assembly and accuracy inspection or finished products, We control quality from raw materials, we always select the best quality raw materials, and we have an quality inspector for each process, quality is always our top concerned.

-

ZK2303A Series CNC Tube-Plate Drilling Machine

The machine tool is a special CNC deep hole drilling machine for processing tube sheet workpieces. Controlled by CNC system, it can be used to process workpieces with coordinate hole distribution. The X-axis drives the cutting tool and column system to move laterally, and the Y-axis drives the cutting tool system to move up and down to complete the positioning of workpiece. The Z-axis drives the rotating tool system to move longitudinally to complete deep hole drilling.

-

CK series CNC lathe with slant bed

This is a CNC double coordinates, two-axis associated-action and semi-closed loop controlled turning lathe. It has the advantage of high accuracy, high efficiency and high stability. Mated with advanced CNC system, the machine has the function of interpolating linearity, oblique line, arc (cylindrical, rotary camber, spherical surface and conic section), straight and taper metric/inch screws. It is suitable for processing complicated and precision plates and shafts. The roughness after turning can reach the accuracy of grinding by other grinder.

-

TSK21200 CNC Heavy Type Deep Hole Drilling And Boring Machine

The machine is a deep hole processing machine, which can complete the drilling, boring and trepanning of deep holes of heavy parts with large diameter. Suitable for maximum drilling diameter Φ 210mm, maximum trepanning diameter Φ 500mm, maximum boring diameter Φ2000mm workpiece with length not more than 25m.

-

bench lathe CZ1237G-1 CZ1337G-1

*4-handles gearbox

*V-way bedways induction hardened and ground;

*Cross and longitudinal interlocking feed, enough safety;

*ASA D4 cam-lock spindle nose;

*Various threads cutting functions available -

double column vertical lathe C52 series

This machine is a double column vertical lathe, which is an advanced equipment with excellent performance, wide range of technology and high production efficiency.

-

Deep Hole Drilling And Boring Machine T2150/T2250 Series

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

CNC pipe threading lathe, oil field & hollow spindle lathe Q1313-1319-1322 series

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed

This deep hole powerful honing machine is equipped with PLC controller or CNC system (optional), linear rolling guide way, AC servo motor, grinding rod adopts stepless speed regulation, stable commutation, convenient speed regulation, easy to ensure the accuracy of hole size, and reduce labor intensity. In the honing process, the sand rod and the workpiece always maintain constant pressure, so that the sand rod can be strongly ground. It ensures the high efficiency of deep hole machining, and is suitable for rough and fine honing of general cylindrical deep hole parts. This type of machine tool can also be used for partial honing to correct the taper and ellipticity of parts and the partial hole error.