Products

-

boring head, boring and rolling combined tool

TJ type roller-adjustable rough Comparing to the conventional boring head, the new type has the following advantage: Guide by roller, with multi-point support and stable guide performance. The point contact between the roller and the inner wall of the workpiece reduces the friction and prolongs the using life; more importantly, it avoids the trouble of replacing frequently the guide pad. The productivity can be increased by double. The size can be adjusted in the range of 5mm, it doesn’t need... -

CH61200L CNC turning center with C axis

This machine is mated with C axis, feed X and Z axis, three axis can be linkage and move together with multi-function and high cutting efficiency.

-

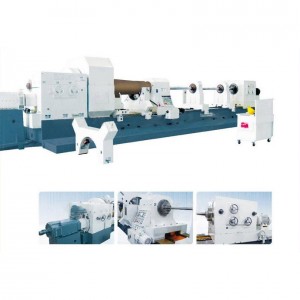

Four guide ways heavy duty horizontal CNC lathe CK61250F series

The ck61xxf series is an improved series of heavy-duty horizontal CNC lathes with four guide ways developed by our company based on our long-term experience in horizontal lathe production and adopting internationally advanced design means and manufacturing technology. It implements the latest national accuracy standards and is meticulously designed by integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool products integrating multiple categories of precision manufacturing technology. The structure and performance of the machine tool are applicable. The machine tool has the characteristics of high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

-

Three guide way heavy duty horizontal engine lathe CWZ61160-CWZ61250

This machine tool is a universal heavy duty lathe with three guide ways, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. And can use the upper slide (through the change gears) to turn various threads with a length shorter than 600mm (full-length thread can be processed for special orders).

-

multi-purpose machine G1324,G1340

*Has the purposes of turning, milling, drilling, boring and thread-cutting. *DC brushless motor, big torque at low speed, infinitely variable speed. *Power driven for table in milling. *Cam clamping chuck. *Lengthened table. *Has the devices of safety interlock and an overload safety. *Lengthened drilling/milling box, 360o rotation in horizontal plane.

-

Deep Hole Drilling And Boring Machine, deep hole BTA drilling machine TQ2180

TQ2180 is a cylinder drilling and boring machine, which can perform the function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring.

-

bench lathe CZ1340G CZ1440G

*Norton lever gearbox.

*Engineered from high grade castings;

*Supersonic frequency hardened bed ways;

*Precision roller bearing for spindle;

*High quality steel,ground and hardened gear inside headstock;

* Easy and fast operating gearbox;

*Enough strong power motor;

*ASA D4 camlock spindle nose;

*Metric/Imperial threads cutting functions availableAll our products have to go through three separate checks throughout the whole manufacturing process: iron casting and all kinds of purchased parts and self-made parts, each part for machine assembly and accuracy inspection of final finished product, We control quality from raw materials, we always select the best quality raw materials, for example, resin sand iron casting with HT300 and famous brand electric elements, and we have an quality inspector for each process, quality is always our top concerned. we welcome all the customers from all over the world for cooperation.

-

bench lathe CZ1340G-1 CZ1440G-1

* Ultra audio frequency quenching bed guide way;

* Spindle is mated with precision roller bearings;

* Gears inside headstock were hardened and ground.

* Gearbox is easy operating.

* Motor is strong enough;

* Spindle nose is ASA D4 camlock type;

* Various threads cutting functions available.All our bench lathes have to go through three separate checks throughout the whole manufacturing process: iron casting and all kinds of purchased and self-made parts, each machincal part for machine assembly and accuracy inspection of finished product, We control quality from raw materials, we always select the best quality raw materials, for example, resin sand iron casting with HT300 materal and famous brand electric elements, and we have an quality inspector for each process, quality is always our top concerned. we welcome all the customers from all over the world for cooperation.

-

bench lathe CZ1340A CZ1440A

*brake equipment can make spindle stop very quickly, but motor don’t stop for better protection

*Supersonic frequency hardened bed ways;

*Precision roller bearings for spindle;

*High quality steel,ground and hardened gears inside headstock;

* Easy and fast operating gearbox;

*Enough strong power motor;

*ASA D4 camlock spindle nose;

*Various threads cutting functions available -

Large deep hole drilling and boring machine, deep hole BTA drilling machine T21100/T21160

T21100/T21160 series is a deep-hole machining machine, which can support the process of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring.

-

Deep Hole Drilling And Boring Machine T2180/T2280

T2180 is a big cylinder drilling and boring machine, which can perform the processing function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal method is used for drilling and forward metal chips removal inside boring rod by cutting liquid for boring.

-

horizontal engine conventional lathe CW6163E,CW6180E,CW61100E,CE61200E

The lathe bed is of an integral floor type structure. It is integrally cast. After casting and rough machining, it is subject to aging treatment to ensure the structural rigidity of the whole machine. The guide way surface is subject to medium frequency quenching, the hardness is not less than HRC52, the hardening depth is not less than 3mm, and the stability of the whole machine is good.

The reasonable structure design ensures that the lathe has sufficient static and dynamic rigidity. The advanced technology ensures that the machine has good quality, low noise and small vibration.

Beautiful appearance, combined with ergonomic principles, easy adjustment of workpieces, easy operation and maintenance.

The main parts such as the bed, headstock, carriage and tailstock are made of high-quality resin sand castings. After natural aging and artificial aging, the main parts of the machine are guaranteed to have low deformation and high stability.

The spindle adopts a three support structure, with reasonable span, low noise, low heat generation and good accuracy retention.

The spindle has a wide speed range, stable operation, low temperature rise and good accuracy retention.

The main transmission gear is hardened and ground to ensure its high accuracy, smooth operation and low noise.

High cutting power and high processing efficiency.