Products

-

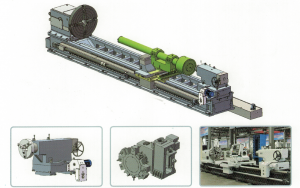

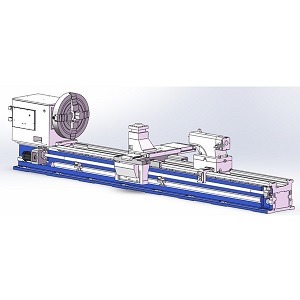

CKT61125/160/200B CNC HORIZONTAL LATHE WITH BORING BAR

This machine is a multifunctional lathe developed by our company on the basis of a large flat-bed CNC horizontal lathe with boring function. The bed is optimized, the overall weight is increased, the carriage is lengthened, widened, and thickened, and a dedicated boring tool holder is supplied. It can cut the inner holes of parts, and the processing efficiency, accuracy, and rigidity are better than ordinary CNC lathes. Adopting a semi enclosed protective structure and equipped with Siemens s... -

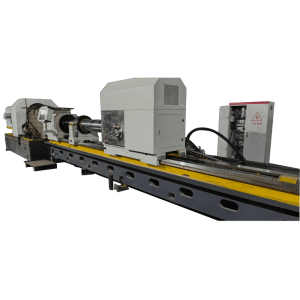

ZQK42 series CNC deep hole drilling machine for crankshaft, CNC 7-axis oil hole of crankshaft drilling machine

This equipment is a specialized machine for processing deep holes in the crankshaft, using the external chip removal method (gun drill) to process the deep holes on the crankshaft. The axial movement of the rotating power head and the processing of drilling depth are all using CNC methods, while the rotation of the crankshaft and the angle rotation of the power head can be by servo driving methods. During processing, the workpiece is through the A-axis angular rotation servo axis to locate an... -

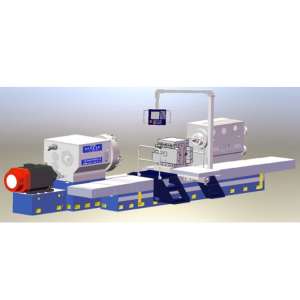

CNC ROLL LATHE

The machines can be equipped with milling, grinding, boring units, etc. so that they can carry out the most varied machining.

-

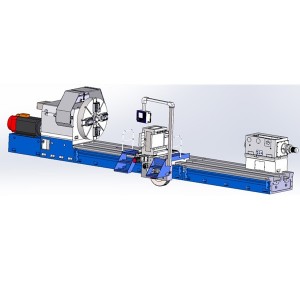

CKF SERIES CNC HEAVY DUTY HORIZONTAL LATHE

The machines can be equipped with milling, grinding, boring units, etc. so that they can carry out the most varied machining.

-

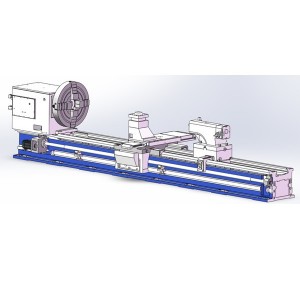

CKB SERIES CNC HORIZONTAL LATHE

The machines can be equipped with milling, grinding, boring units, etc. so that they can carry out the most varied machining.

-

CKA SERIES CNC HORIZONTAL LATHE

The machines can be equipped with milling, grinding, boring units, etc. so that they can carry out the most varied machining.

-

Deep-hole trepanning machine TK2150

I. Basic process performance of the machine 1) This machine can be used for trepanning the internal holes. 2) During machining, the workpiece rotates, the cutting tool feeds, and Cutting fluid enters the cutting area through the trepanning bar to cool and lubricate the cutting area and take away the metal chips. 3) When trepanning, the rear end of the trepanning bar is used for oil supply, and the end of the oil pressure head is used for cutting. 6) The machining accuracy of the machine tool:... -

Deep Hole Pull Boring Machine TLS2210A/TLS2220B for centrifugal casting pipe

The machine is a specially used for boring long and thin pipes. It adopts the processing mode of workpiece rotation (passing through the spindle hole of headstock) and cutting tool bar is fixed and only for feed motion. When boring, the cutting fluid is supplied by the oil pressure head, and the cutting chips are discharged forward. The cutting tool feed adopts AC servo drive system to realize stepless speed regulation. Headstock adopts multi-stage gear speed change, with a wide speed range. Mechanical locking device is used for clamping of the oil pressure head and workpiece.

-

HM series Sunnen type deep hole honing machine

HM series Sunnen type deep hole honing machine is mainly used for finishing the cylindrical inner hole surface of various hydraulic cylinders, steel pipes, etc. The aperture accuracy is above IT7, and the surface roughness is Ra0.2-0.4 μ m.

-

Trepanning head and other special tool

ZT type trepanning head Trepanning head is also named as annular drill, it is an economic, productive and high quality deep hole tool, its productivity is more than times the ordinary drill. It is better to use trepanning tool for machining the hole above 50mm in diameter. This tool is applicable to the following conditions: 1) Hole diameter is 50mm above, and with the close tolerance on straightness and position precision. 2) 2) the length-to-diameter ratio of the hole is in the r... -

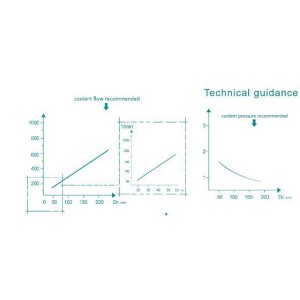

Technical guidance

The cutting parameters are for reference only and adjusted according to the actual processing conditions. Compared with the mixed lotion, the pure oil can improve the service life of the tool.

-

SRB tool, honing head, honing rod and bushes

SRB Pnumatic tools SRB head Boring rod SRB head Boring rod SRB head Boring rod Φ35- 37 Φ30 Φ38-45 Φ43 Φ46-56 Φ43 Φ57-60 Φ51 Φ61-69 Φ56 Φ70-89 Φ65 Φ90-120 Φ80 Φ121-139 Φ100 Φ140-169 Φ130 Φ170-230 Φ160 Φ231-400 Φ220 Operation: the tool moves forward for skiving, and backward fo roller burnishing. With 2 groups of inserts on the top end, it can achieve high sizing precision and good shape control. With 4 groups of guide pad, it can achieve the excellent guidance and balanced ski...