PriceList For Deep Hole Skiving And Roller Burnishing Machine - Deep Hole Turning and Boring Machine TCS2150 – Premach

PriceList For Deep Hole Skiving And Roller Burnishing Machine - Deep Hole Turning and Boring Machine TCS2150 – Premach Detail:

Function Description

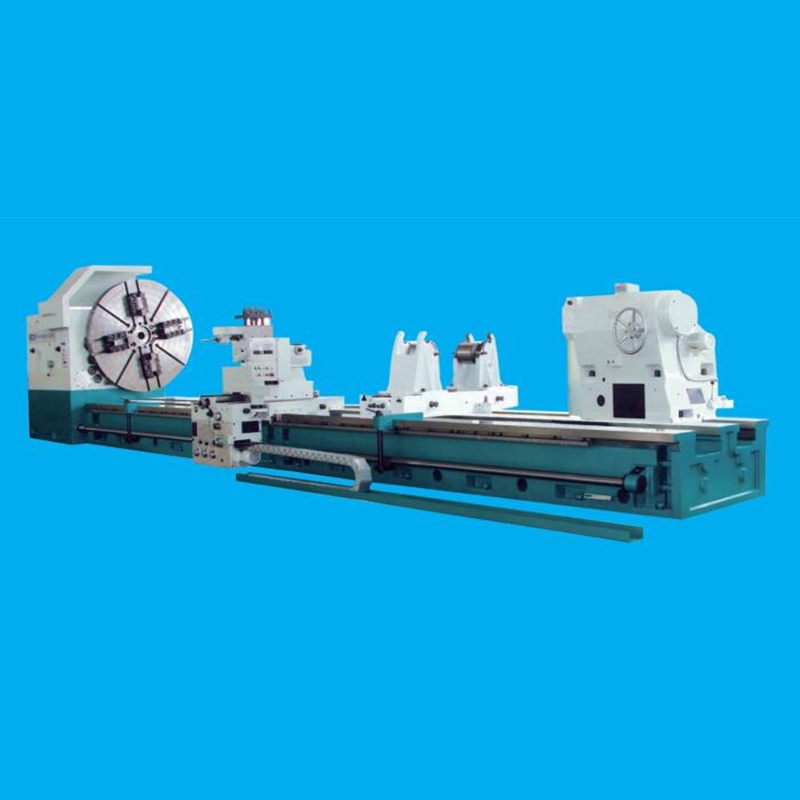

The machine is installed with work headstock and travel head with rotating drilling/boring rod, both workpiece and tool can rotate, and the cutting tool can also be fixed, only feed.

In addition, this machine is also installed a toolpost like that of the lathe, so that the machine adds the function of turning outer circle on the basis of deep hole drilling and boring machine. The machine is a series of products, and can also provide various modified products according to customer requirements.

The machine consists of bed, work headstock, lantern of chuck, open steady rest, stead rest, oil pressure head, vibration damper steady of boring rod, travel head with rotating drilling/boring rod, coolant system, electric system, hydraulic system, chip removing device, lubrication system, turning tool post etc.

the four jaw chuck is installed on the work headstock while drilling, and while boring, two taper plates are used, one is installed on the front end of the spindle on the work headstock, another is installed on the oil pressure head, the taper plates are much more convenient for self-centering, in general condition, the degree of the taper plates is 15°, the detailed requirement of the taper plates is determined by the size of the workpiece. The customer can also choose the other clamp method. There is a taper plate in front of the oil pressure head (oil supply device), and there is a guide bush inside of the taper plates, which is used for guide drilling/boring head, this guide bush must be changed when the cutting tool is to be changed.

Technical parameter

|

Working Capacity |

Range of drilling Dia. | Φ40-Φ120mm |

| Max. boring Dia. | Φ500mm | |

| Max. boring depth | 1-16m | |

| Max. turning outer Dia. | Φ600mm | |

| Workpiece clamped Dia. range | Φ100-Φ660mm | |

|

Spindle |

Center height from spindle center to bed | 630mm |

| Spindle bore Dia. | Φ120mm | |

| Taper of spindle bore | Φ140mm, 1:20 | |

| Range of spindle speed | 16-270rpm, 12 kinds | |

|

Travel head with rotating drilling bar |

Spindle bore Dia. of travel head with rotating drilling bar | Φ100mm |

| Taper of spindle bore (travel head with rotating drilling bar) | Φ120mm, 1:20 | |

| Range of spindle speed (travel head with rotating drilling bar) | 82-490rpm, 6 kinds | |

|

Feed |

Feed speed range (infinite) | 0.5-450mm/min |

| Rapid travel speed of carriage | 2m/min | |

|

Motors |

Main motor power | 45KW |

| Motor power of travel head with rotating drilling bar | 30KW | |

| Motor power of hydraulic pump | 1.5KW, n=1440rpm | |

| Rapid travel motor power of carriage | 5.5KW | |

| Feed motor power | 7.5KW (servo motor) | |

| Motor power of cooling pump | 5.5KWx3 + 7.5KWx1 (4 groups) | |

| Motor of Z axis | 4KW | |

| Motor of X axis | 23N.m (stepless) | |

|

Others |

Rated pressure of cooling system | 2.5MPa |

| Flow of cooling system | 100,200,300,600L/min |

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for PriceList For Deep Hole Skiving And Roller Burnishing Machine - Deep Hole Turning and Boring Machine TCS2150 – Premach , The product will supply to all over the world, such as: Senegal, Latvia, Botswana, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

This supplier stick to the principle of Quality first, Honesty as base, it is absolutely to be trust.