Price Sheet for Customized Face End CNC Lathe for Turning Side Plate of Tyre Mold (CK64100)

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for Price Sheet for Customized Face End CNC Lathe for Turning Side Plate of Tyre Mold (CK64100), We’re glad that we have been steadily increasing with the lively and long-term aid of our satisfied buyers!

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for China Tyre Mold Lathe and CNC Face Lathe, The quality of our solutions is equal to OEM’s quality, because our core parts are the same with OEM supplier. The above goods have passed experienced certification, and we not only can produce OEM-standard solutions but we also accept Customized Solutions order.

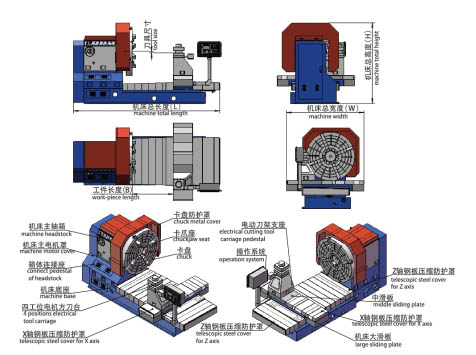

Protection device of machine rotation parts

The pull and push device is installed on the Machine rotation part (such as chuck and Motor) to prevent the fall off of workpiece Due to centrifugal force, and ensure the machine and operator’s safety. This design meets with safety standard of machine design.

Center design of sliding platec srew+flat

guide way design+dovetail rail positioning dual axis of machine are all driven by high precision ground ball screw which are all central design to avoid the pulling deviation during transmisioin process and guarantee the machining accuracy. Guide way are do Vetail type as sliding positioning while the Flat guide way as sliding support to ensure. The positioning accuracy and stability of Sliding plate.

Bus termination operation system

The machine CNC system adopts bus termination operation system and high advanced CNC control systems like GSK, SIEMENS, FANUC, etc with manual pulse Generator to realize convenient operation with stable signal transmission and high

Accuracy.

High accuracy headstock

40Cr forged and ground gears are used in the headstock with 4 gear shifts speed regulation. All shafts are spline structure with tight fit. The standard configuration of bearings are Harbin, Wa and Luo brands with high accuracy. The gear meshes with high accuracy and low noise.

Product range

Product overview

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

Overall size drawing

Technical Parameter

| Model | CK64125 | CK64160 | CK64200 | CK64250 | CK64300 |

| Swing diameter over bed | Φ1250mm | Φ1400mm | Φ2000mm | Φ2500mm | Φ3000mm |

| Swing diameter over carriage | Φ800mm | Φ1250mm | Φ1600mm | Φ2000mm | Φ2500mm |

| Guide way width of machine bed | 850mm | 1000mm | 1250mm | 1250mm | 1250mm |

| Chuck diameter | Φ1000mm | Φ1250mm | Φ1600mm | Φ2000mm | Φ2500mm |

| Length of chuck jaw seat | Embedded chuck jaws | Embedded chuck jaws | 400mm | 500mm | 800mm |

| Workpiece loading weight | 2000kg | 3000kg | 4000kg | 5000kg | 5000kg |

| Spindle speed gears | 3 gear shifts | 3 gear shifts | 3 gear shifts | 3 gear shifts | 3 gear shifts |

| Spindle speed | 6-210rpm stepless | 4-140rpm stepless | 4-106rpm stepless | 3-87rpm stepless | 3-87rpm stepless |

| X axis rapid travel speed | 3000mm/min | 3000mm/min | 3000mm/min | 3000mm/min | 3000mm/min |

| Z axis rapid travel speed | 3000mm/min | 3000mm/min | 3000mm/min | 3000mm/min | 3000mm/min |

| Electric turret size | 280mmx280mm | 280mmx280mm | 300mmx300mm | 300mmx300mm | 300mmx300mm |

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for Price Sheet for Customized Face End CNC Lathe for Turning Side Plate of Tyre Mold (CK64100), We’re glad that we have been steadily increasing with the lively and long-term aid of our satisfied buyers!

Price Sheet for China Tyre Mold Lathe and CNC Face Lathe, The quality of our solutions is equal to OEM’s quality, because our core parts are the same with OEM supplier. The above goods have passed experienced certification, and we not only can produce OEM-standard solutions but we also accept Customized Solutions order.