OEM/ODM Manufacturer Horizontal Bore Drilling - TSK21200 CNC Heavy Type Deep Hole Drilling And Boring Machine, cylinder boring machine – Premach

OEM/ODM Manufacturer Horizontal Bore Drilling - TSK21200 CNC Heavy Type Deep Hole Drilling And Boring Machine, cylinder boring machine – Premach Detail:

Video Display

Function Description

The machine tool is suitable for processing large hydraulic cylinders, high-pressure boiler tubes, pipe molds, wind turbine shafts, ship transmission shafts and nuclear power tubes.

According to the characteristics of trepanning process, the machine tool is designed to be equipped with relevant parts, special cutter rods, cutters and special trepanning parts, so that the machine tool is more suitable for deep hole trepanning process.

There are two process forms during processing:

A. workpiece rotate, cutting tool reverse rotating and feed;

B. the workpiece rotates and the cutting tool does not rotate but only feeds.

Drilling or boring diameter less than Φ 210, the BTA internal mental chip removal process of oil pressure head supplying cutting fluid, discharging chips and cutting fluid in the inner hole of drilling/boring rod is adopted.

During boring and rolling, the boring rod is provided with cutting fluid to discharge cutting fluid and metal chips forward (at the head of the machine).

During trepanning bigger holes, the process of external chip removal is adopted, the trepanning rod does not rotate and the workpiece rotates. During trepanning smaller holes, adopting the internal chip removal process, both the trepanning rod and workpiece can be rotated.

Technical parameter

| TSK21200 | ||

|

Working capacity |

Range of drilling Dia. | Φ50-Φ210mm |

| Boring Dia. range | Φ50mm-Φ2000mm | |

| Drilling/boring depth range | 2-25m | |

| Range of trepanning Dia. | Φ80-500mm | |

| Max. Dia. of boring rod | Φ460mm | |

| Clamping diameter range of main chuck | Φ600-Φ2200mm | |

| Clamping diameter range of assistant chuck | Φ200-Φ600mm | |

| Clamping diameter range of closed steady rest | Φ200-Φ1200mm | |

| Max. loading weight of closed steady rest | 40 ton | |

| Clamping diameter range of opened steady rest | Φ200-Φ1200mm | |

| Max. loading weight of opened steady rest | 60 ton | |

| Max. loading weight of machine with single roller support | 120 ton | |

| Max. loading weight of machine with more than double roller supports | 150 ton | |

| Max. loading weight of machine with single steady rest | 80 ton | |

| Max. loading weight of machine with more than double steady rests | 100 ton | |

| Headstock | Center height from spindle center to bed | 1700mm |

| Spindle bore Dia. | Φ70mm | |

| Taper of spindle bore | Φ140mm, 1:20 | |

| Range of spindle speed | 0.5-180rpm, 2 gears, stepless | |

| Rapid moving speed | 2m/min | |

| Rack used for moving headstock | Slant teeth, m10 | |

| Max. travel of headstock | 21m | |

|

Travel head with rotating drilling bar |

Spindle bore Dia. of travel head with rotating drilling bar | Φ120mm |

| Taper of spindle bore (travel head with rotating drilling bar) | Φ140mm, 1:20 | |

| Range of spindle speed (travel head with rotating drilling bar) | 3-400rpm, 3 gears | |

| Center height of spindle | 800mm | |

| Rack used for moving travel head with rotating boring rod | Slant teeth, m10 | |

| Max. travel of travel head with rotating boring rod | 27m | |

|

Feed |

Feed speed range (infinite) | 0.5-200mm/min |

| Rapid travel speed of carriage | 2m/min | |

|

Motors |

Main motor power | 110KW |

| Motor power of travel head with rotating drilling bar | 55KW | |

| Motor power of hydraulic pump | 1.5KW, n=144rpm. | |

| Travel motor power of headstock | 7.5KW, A.C. servo motor | |

| Feed motor power of carriage | 11.7KW,2000r/min, (A.C. servo motor) | |

| Motor power cooling pump | 5.5KWx2 groups, 22KW (2 groups) | |

| General motor power (Approx.) | 245KW | |

|

Others |

Guide way width of workpiece | 1600mm |

| Guide way width of travel head with rotating boring rod | 1250mm | |

| Reciprocating travel of oil pressure head | 250mm | |

| Rated pressure of cooling system | 2.5MPa (400L/min), 8MPa (200L/min) | |

| Flow of cooling system | 100,200,300,400L/min | |

| Rated working pressure for hydraulic system | 6.3MPa | |

| Control system | Siemens 828D or others | |

| Overall size for 25m machine | 66mx7mx4m | |

| General weight of machine (Approx.) | 26 ton |

Machining Accuracy

Machining Accuracy of machine (related to workpiece material, heat treatment condition, cutting parameters and cutting oil):

When drilling: aperture accuracy IT9 ~ 10, surface roughness Ra6.3 ~ 12.5;

During trepanning: aperture accuracy IT9 ~ 10, surface roughness Ra6.3 ~ 12.5;

During rough boring: aperture accuracy IT9 ~ 10, surface roughness Ra3.2 ~ 6.3;

During fine boring: aperture accuracy IT8 ~ 9, surface roughness Ra1.6 ~ 3.2;

During rolling: aperture accuracy IT8 ~ 9, surface roughness Ra0.4 ~ 0.8;

Straightness of machined hole (after finishing): less than 0.15/1000mm;

Deflection of machined hole (after finishing): less than 0.3/1000mm.

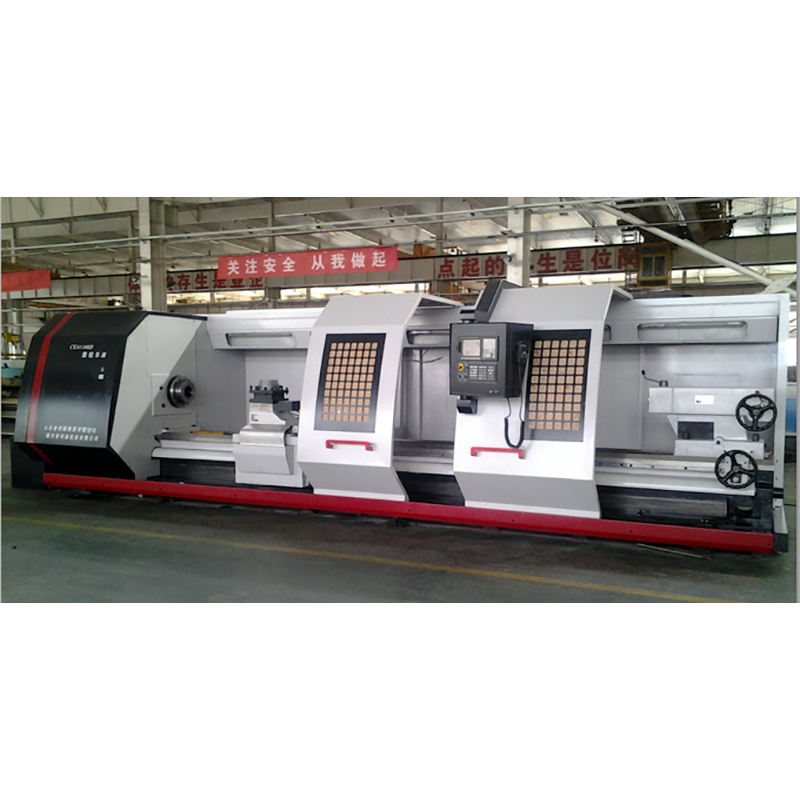

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for OEM/ODM Manufacturer Horizontal Bore Drilling - TSK21200 CNC Heavy Type Deep Hole Drilling And Boring Machine, cylinder boring machine – Premach , The product will supply to all over the world, such as: UK, Iran, Jersey, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.