ODM Manufacturer 2 Axis Drilling CNC Machine Wood Automatic CNC 4 Side 6 Sides Boring Drilling Machine

Our pursuit and company goal is to “Always satisfy our customer requirements”. We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for ODM Manufacturer 2 Axis Drilling CNC Machine Wood Automatic CNC 4 Side 6 Sides Boring Drilling Machine, Special emphasis within the packaging of solutions to avoid any damage during transportation,Detailed attention towards the useful feedback and suggestions of our esteemed clients.

Our pursuit and company goal is to “Always satisfy our customer requirements”. We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for China CNC Drilling Machine and CNC Machine, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let’s develop market by fully utilizing our detailed advantages and strive for building.

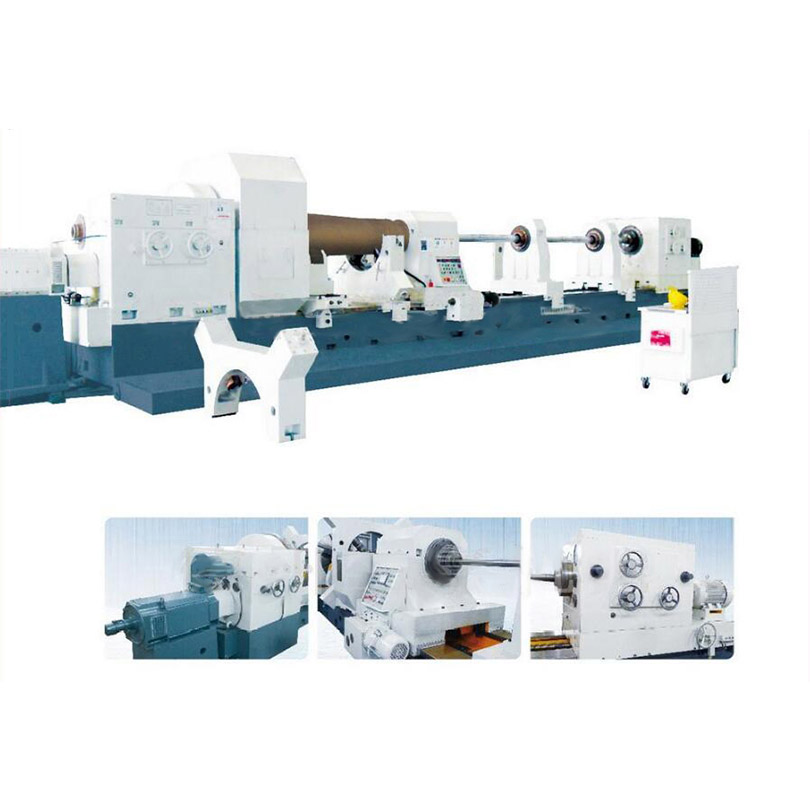

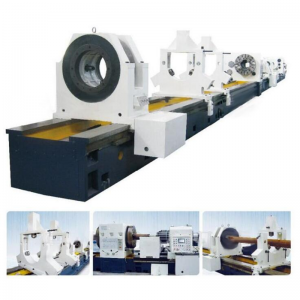

Video Display

Function Description

T2180 is a deep-hole machining machine, which can support the process of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And we used extra metal chip removal technique for trepanning which need professional trepanning cutting tools and special purpose fixture. According to the machining requirement, a travel head with rotating drilling/boring rod is equipped so the drilling/boring tools can rotate and feed.

Technical parameter

| T2180 | T2280 | |||||

|

Working capacity |

Drilling Diameter | Φ50-Φ150mm | / | |||

| Max. boring Dia. | Φ800mm | |||||

| Boring depth range | 1-16m | |||||

| Range of trepanning Diameter | Φ150-500mm | |||||

| Workpiece clamped Dia. range | Φ270-Φ1200mm | |||||

| Spindle | Center height from spindle center to bed | 800mm | ||||

| Spindle bore Dia. | Φ120mm | |||||

| Taper of spindle hole | Φ140mm, 1:20 | |||||

| Range of spindle speed | 1-200rpm, 3 gears with stepless speed | |||||

|

Traveling head with rotating drilling rod |

Spindle hole Dia. of travel head with rotating drilling bar | Φ120mm | / | |||

| Taper of spindle bore (travel head with rotating drilling bar) | Φ140mm, 1:20 | / | ||||

| Spindle speed (traveling head with rotating drilling rod) | 16-270rpm, 12 kinds | / | ||||

|

Feed |

Feed speed range (infinite) | 5-500mm/min | ||||

| Rapid travel speed of carriage | 2m/min | |||||

|

Motors |

Main motor power | 55KW | ||||

| Motor power of traveling head with rotating drilling rod | 45KW | / | ||||

| Motor power of hydraulic pump | 1.5KW, n=144rpm. | |||||

| Rapid travel motor power of carriage | 7.5KW | |||||

| Feed motor power | 7.5KW (servo motor) | |||||

| Motor power of cooling pump | 11KWx2 + 5.5KWx2 | 7.5KWx3 | ||||

|

Others |

Guide way width | 1250mm | ||||

| Rated pressure of cooling system | 2.5MPa | 0.36MPa | ||||

| Flow of cooling system | 200,400,600,800L/min | 300,600,900L/min | ||||

| Rated working pressure for hydraulic system | 6.3MPa | |||||

| Max. axial force of oil pressure head | 68KN | |||||

| Max. pushing force of oil pressure head to workpiece | 20KN | |||||

Overall dimensions and weight

| Length Technical data | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 |

| Occupying Floor space LxWxH (mm) | 13000 | 15000 | 17000 | 20000 | 22000 | 24000 | 26000 | 29000 | 31000 | 33000 |

| X4000 | X4000 | X4000 | X4000 | X4000 | X4000 | X4000 | X4000 | X4000 | X4000 | |

| x2500 | x2500 | x2500 | x2500 | x2500 | x2500 | x2500 | x2500 | x2500 | x2500 | |

| Net weight (T) | 53 | 56 | 59 | 63 | 66 | 69 | 72 | 76 | 79 | 82 |

Our pursuit and company goal is to “Always satisfy our customer requirements”. We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for ODM Manufacturer 2 Axis Drilling CNC Machine Wood Automatic CNC 4 Side 6 Sides Boring Drilling Machine, Special emphasis within the packaging of solutions to avoid any damage during transportation,Detailed attention towards the useful feedback and suggestions of our esteemed clients.

ODM Manufacturer China CNC Drilling Machine and CNC Machine, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let’s develop market by fully utilizing our detailed advantages and strive for building.