Manufacturing Companies for Deep Hole Roller Scraping Machine

We now have quite a few superb workers customers very good at marketing and advertising, QC, and working with forms of troublesome dilemma while in the creation approach for Manufacturing Companies for Deep Hole Roller Scraping Machine, “Change for the greater!” is our slogan, which means “A greater entire world is before us, so let’s love it!” Change for your greater! Are you all set?

We now have quite a few superb workers customers very good at marketing and advertising, QC, and working with forms of troublesome dilemma while in the creation approach for China CNC Deep Hole Skiving Roller Burnishing Machine and CNC Roller Burnishing and Skiving Machine, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

SRB Pnumatic tools

| SRB head | Boring rod | SRB head | Boring rod | SRB head | Boring rod |

| Φ35- 37 | Φ30 | Φ38-45 | Φ43 | Φ46-56 | Φ43 |

| Φ57-60 | Φ51 | Φ61-69 | Φ56 | Φ70-89 | Φ65 |

| Φ90-120 | Φ80 | Φ121-139 | Φ100 | Φ140-169 | Φ130 |

| Φ170-230 | Φ160 | Φ231-400 | Φ220 |

Operation: the tool moves forward for skiving, and backward fo roller burnishing.

With 2 groups of inserts on the top end, it can achieve high sizing precision and good shape control.

With 4 groups of guide pad, it can achieve the excellent guidance and balanced skiving. Also prevent from scraping on the hole surface. The inserts are retracted by pneumatic control.

Feature:

To be used for machining various tubes including cold drawn seamless steel tube, welded cold drawn tube, hot roller steel tube and cast steel tube.

Easily and rapidly adjust the sezes of insetts, guide pads and rollers. At the completion of processing, adjust cartridge by pneumatic control to prevent from damage on the hole furface.

Adopting the design with high efficiency, combining fine skiving and roller burnishing, and achieving one-off machining. It provides the foot with a long life and has a high efficiency of 20 times traditional honing machine and 5-10 times ordinary boring machine.

At the completion of processing, the suface hardness increases about 30%, the precision is up to IT8, surface finish is up to Ra0.05-0.2μm.

To improve compatible precision, increase wear resistance and prolong using life of spare parts. After roller burnishing, oil cylinder becomes anti-corrosive and wear-resistant, and achieving a good surface finish, which prolong the life of sealing ring or sealing parts.

SRB Hydraulic tools

| SRB head | Boring rod | SRB head | Boring rod | SRB head | Boring rod |

| Φ35- 37 | Φ30 | Φ38-43 | Φ43 | Φ44-48 | Φ40 |

| Φ49-60 | Φ43 | Φ61-72 | Φ56 | Φ73-77 | Φ65 |

| Φ78-87 | Φ70 | Φ88-107 | Φ80 | Φ107-137 | Φ100 |

| Φ138-177 | Φ130 | Φ178-250 | Φ160 | Φ250-400 | Φ220 |

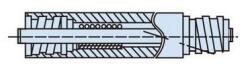

Operation: there is rough boring head on the top end, with three groups of indexable inserts (mechanical clamping) and three groups of carbide guide pad. Rough boring head cuts off most of material, behind with floated skiving head, in which installed three groups (six pieces) of fine inserts. The skiving head reduces wavemark and corrects the deviation on the surface. The back part of the tool is roller burnishing head, with 6-40 rollers working on the internal wall of the bole, which can form the smooth surface and obtain the better profile. At the completion of processing, the skiving insert is shrunk under hydraulic control, while the roller can be also retracted to prevent from damage on the hole surface.

Features

Machining cold drawn seamless steel tube, welded cold drawn tube, hot roller tube and cast tube.

Easily and rapidly adjust the sizes of inserts, guide pades and rlllers. At the completion of action, the skiving cartridge, guide pad and roller are rapidly retracted, effectively protecting against damage on the hole surface.

Adopting the design with high-efficiency, integrating five procedures into one-off process to remove a big stock removal, which significantly improves productivity being 20 times traditinal honing machine and 5-10 times ordinary deep hole boring machine, meanwhile prolong the using life of tools.

After processing, the surface hardness increases about 30%, the prcision is up to IT8 above. Roughness is up to Ra0.05-0.2μm.

After prcessing, the surface hardness increas about 30%, the precision is up to IT8 above. Roughness is up to Ra0.05-0.2μm.

To improve compatible precision, increases wear resistance and prolong using life of spare parts. After roller burnishing, oil-cylinder becomes anti-corossive and wear-resistant, achieving excellent surface finish, and prolonging the life of sealing ring or sealing parts.

MS type deep hole honing

This honing head is used for finish processing of deep hole workpiece.

| Honing head | Honing rod | Honing head | Honing rod |

| Φ38-49.9 | Φ35 | Φ200-349.9 | Φ100 |

| Φ50-79.9 | Φ45 | Φ350-499.5 | Φ130 |

| Φ80-119.9 | Φ70 | Φ500-1000 | Φ230 |

| Φ120-200 | Φ85 |

Honing rod

The honing rod consist of external rod and core pole which can adjust the length of honing rod varying from 1m, 1.2m, 1.5m and 2m to adapt to different machine and different needs. The match of honing head and honing rod please find the above table.

Drilling/boring rod

This drilling/boring rod can be jointed with drilling/boring/rolling/trepanning head, the length of the rod could be 0.5m, 1.2m, 1.5m, 2m etc. to adapt different machine.

Bushes and accessories

Taper bush accessories

We can make the professional deep hole cutting tools according to the customer’s special requirement, e.g., rising tool, forming tool etc.We now have quite a few superb workers customers very good at marketing and advertising, QC, and working with forms of troublesome dilemma while in the creation approach for Manufacturing Companies for Deep Hole Roller Scraping Machine, “Change for the greater!” is our slogan, which means “A greater entire world is before us, so let’s love it!” Change for your greater! Are you all set?

Manufacturing Companies for China CNC Deep Hole Skiving Roller Burnishing Machine and CNC Roller Burnishing and Skiving Machine, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.