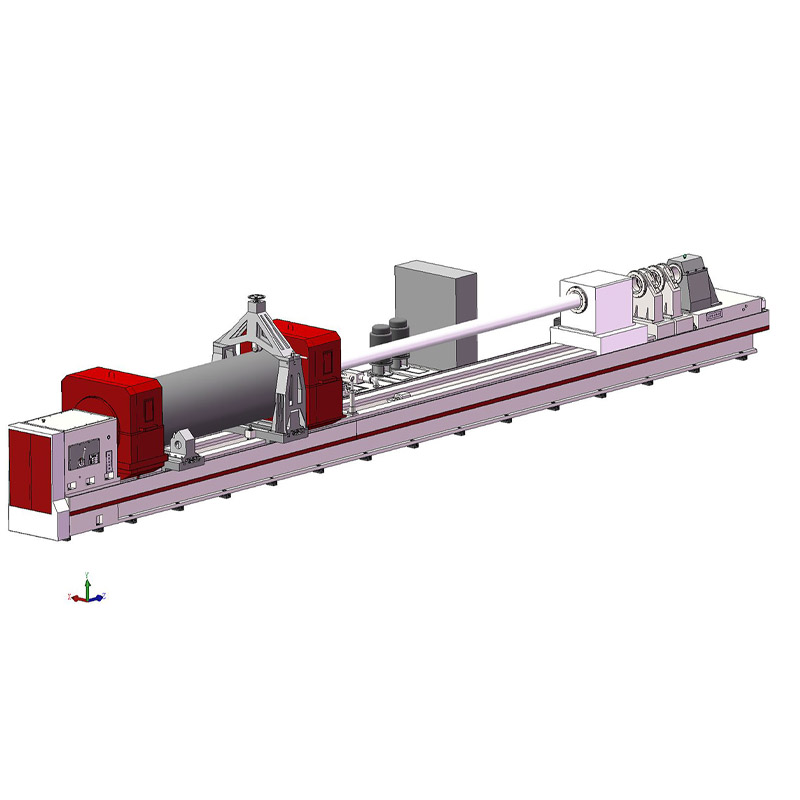

Low MOQ For Cnc Engine Boring Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Low MOQ For Cnc Engine Boring Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach Detail:

Function Description

2.1 Boring

By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge.

One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack.

The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly returns to the boring oil tank.

The ball screw installed on the bed is used to drive the cutting tool to move in Z direction.

When boring, the feeding saddle and the vibration damper steady move on the casting guide way.

2.2 Honing

vibration damper steady of boring move to the rightmost end of the machine, loosen the boring tube by these vibration damper steady and fix the boring tube on the larger vibration damper steady, now the boring tube become honing tube and larger vibration damper steady become the feeding saddle of honing; install the vibration damper steady of honing tube on the machine; install the hydraulic expansion and contraction device of honing head on the left end of the honing tube, and then install the honing head. The connection of the honing head is universal connection.

Remove the chip box on the oil tank, and put the honing recycle oil tank directly under the chip removal device, so that the honing oil can be sent to the honing oil tank through the pump on the recycle oil tank for recycling.

In honing, the servo motor drives the rack and pinion mechanism to realize the movement of feeding saddle of honing on the linear guide way.

Technical parameter

| Boring/honing diameter range | Φ100~Φ800mm |

| Max. Machining depth | 4000mm |

| Workpiece length range | 1000mm-4000mm |

| Center height (from flat guide way to spindle center | 700mm |

| Width of casting guide way | 800mm |

| Clamping diameter range of steady rest | Φ500~Φ1000mm |

| Main motor of headstock | 45KW (servo spindle motor) |

| Spindle speed of headstock | 12~300r/min (manual 3 gears, spepless speed between gears) |

| Taper hole of front end of spindle | 140# |

| Feed speed range of feeding saddle of boring | 5~1000mm/min (stepless speed) |

| Rapid travel speed of feeding saddle of boring | 2500mm/min |

| Feed speed range of feeding saddle of honing | 5000mm~8000mm/min (stepless speed) |

| Rapid travel speed of feeding saddle of honing | 15000mm-20000mm/min |

| Servo motor of driving feed of boring tool | 7.5KW |

| Servo motor of driving feed of honing tool | 5.5KW |

| Motor of cooling pump | 5.5 kw ×3 groups |

| Rated pressure of cooling system | 0.5MPa |

| Flow of cooling system | 200, 500, 800L/min |

| Volume of oil tank | 5000L |

| Size of machine (LxW) | 16m×3.5m |

| Weight of machine | Approx. 28 tons |

| Max. Workpiece loading weight | 12 tons |

| General power of machine(approximate) | 80KW |

| Four jaw chuck | φ1000 |

Machning Accuracy

Boring

Aperture accuracy IT8-9

Surface roughness: Ra3.2μm

Straightness:0.1/1000mm.

Honing

Aperture accuracy IT7-8

Surface roughness:Ra0.8-1.6μm

Cylindricity:0.09mm/total length

Roundness:0.05mm/total length

Standard Accessories

One set of steady rest, two sets of support jacks, two sets of vibration damper steadys, one set of 1000mm four jaw chuck, one set of boring coolant system and one set of honing coolant system.

Optional Accessories

Cutting tools: boring head, honing head, boring/honing tube and relative bushes, cutting oil and trepanning function.

Note: Due to continuous improvement and development, the design and specification change without notice.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, belief the very first and management the advanced for Low MOQ For Cnc Engine Boring Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach , The product will supply to all over the world, such as: The Swiss, Uruguay, Indonesia, Our tenet is integrity first, quality best. We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,