Lathe

-

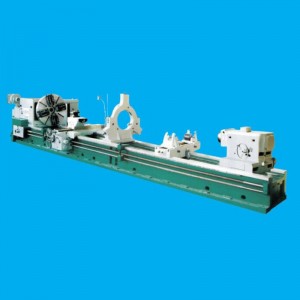

horizontal engine lathe CWA61100-CWA61160

This machine tool is a universal conventional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

horizontal engine conventional lathe CW6163,CW6180(A),CW61100(A),CE61200(A)

This machine tool is a universal engine concentional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

horizontal engine conventional lathe CW61128-CW611208

This series of engine conventional lathes can undertake various turning tasks. It can turn the outer circle, inner hole, end face, metric thread, inch thread, modulus and pitch thread and other shaped surfaces of various parts. The upper slide can be used to turn short tapers independently. The upper slide can also be used to machine long tapers when it is matched with the longitudinal feed of carriage. It can also meet the process requirements of drilling, boring and trepanning. It is also suitable for powerful turning with carbide tools, Processing of various ferrous and non-ferrous metals.

-

horizontal engine conventional lathe CW61126-CW611206

This series of engine conventional lathes has been continuously updated and improved by our company for more than 40 years, after absorption of advanced design and manufacturing technologies at home and abroad, and after use of users in aerospace, railway, valve and other industries, the practice has proved that the large horizontal lathes produced by our company have reached the advanced level in China.

The technical features of this series of lathes are as follows: first, the basic parts, the spindle tailstock quill, etc. have passed the optimization design and fine processing, with high precision and life; second, the key components, such as the spindle bearings and the main electrical components, are all famous brands at home and abroad.

-

CNC pipe threading lathe,oil field & hollow spindle lathe QKD1325-1330-1335 series

This series of machine tools are mainly used for pipe thread processing, and can cut metric and inch cylindrical and conical pipe threads. It is suitable for processing tubing, casing, drill pipe, etc. in petroleum, metallurgy, chemical, hydropower, geology and other departments.

Mated with CNC system, with high control precision and good reliability. The machine tool can also adopt PLC controller, which improves the reliability and control flexibility of the machine tool.

-

CNC horizonta lathe machine SKQ61100 series

MODEL SKQ61100 SWING Φ1000mm SKQ61125 SWING Φ1250mm SKQ61140 SWING Φ1400mm SKQ61160 SWING Φ1600mm Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRT display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback. The overall bed guide way is made of high-strength cast iron and ground after ultra- audio frequency quenching. The guide way of bed saddle is pasted with plastic, and the friction coefficient is small.

-

CNC end face turning lathe

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

double column vertical lathe C52 series

This machine is a double column vertical lathe, which is an advanced equipment with excellent performance, wide range of technology and high production efficiency.

-

bench lathe CZ1237G-1 CZ1337G-1

*4-handles gearbox

*V-way bedways induction hardened and ground;

*Cross and longitudinal interlocking feed, enough safety;

*ASA D4 cam-lock spindle nose;

*Various threads cutting functions available -

CNC lathe machine CAK series

CAK6130d series is a high-speed, high-efficiency and economical CNC lathe. It has the processing functions of turning cylindrical surface, conical surface, circular arc surface, inner hole, groove cutting and various threads. It is suitable for the single piece, small batch or batch production of various parts

-

Three guide ways heavy duty horizontal CNC lathe C61200S series

The C61xxS series is an improved series of heavy-duty horizontal lathes with three guide ways developed by our company based on our long-term experience in producing horizontal lathes and adopting internationally advanced design means and manufacturing technology. It is a well-designed product integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool products integrating multiple categories of precision manufacturing technology. The structure and performance of the machine tool are applicable. The machine tool has the characteristics of high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

-

Heavy duty horizontal CNC lathe CG series

This series of heavy-duty horizontal lathes is a kind of well-designed and multi-disciplinary lathe integrating electrical, automatic control, hydraulic control and modern mechanical design, which is based on the our company’s long-term experience in the production of horizontal lathe. has absorbed the advanced technology of the international era, adopted the international advanced design means and manufacturing technology, such as three-dimensional modeling, simulation design, finite element analysis, etc. Mechatronic machine tool products integrating multiple categories of precision manufacturing technology.