Hot New Products Slant Bed - CK series CNC lathe with slant bed – Premach

Hot New Products Slant Bed - CK series CNC lathe with slant bed – Premach Detail:

Property of the lathe

This is a CNC double coordinates, two-axis associated-action and semi-closed loop controlled turning lathe. It has the advantage of high accuracy, high efficiency and high stability. Mated with advanced CNC system, the machine has the function of interpolating linearity, oblique line, arc (cylindrical, rotary camber, spherical surface and conic section), straight and taper metric/inch screws. It is suitable for processing complicated and precision plates and shafts. The roughness after turning can reach the accuracy of grinding by other grinder.

Adopting 450 slant ground bed, the large section of the bed and the large span of the guide way improves the rigidity of the machine, and both X and Z axis are equipped with high rigidity rectangle hardened guide way.

The transmission system of the spindle adopts A.C servo motor with big vary speed range, the spindle adopts hydraulic two grades stepless speeds,

The lubrication is out cycle watery oil structure. And the machine can realize stepless adjusting speed and constant line cutting.

Both X and Z axis are mated with A.C servo motor which has high positioning accuracy and stable performance. The servo motors are connected with ball screw directly, and the small reversal gap and pre-pulling eliminate the affection of the temperature raise to accuracy.

The tailstock is hydraulic and its spindle can be controlled by CNC system.

Turret: it is 12 tool position, and its repeat positioning accuracy is 0.006mm. if need, the machine can also change to hydraulic turret or servo turret.

Chuck: the chuck is hydraulic power chuck, if need, it can also change to pneumatic chuck.

Hydraulic system: hydraulic system adopts variable impeller pump, the pressure of the hydraulic system is 5. Mpa, the hydraulic elements are all made in Taiwan. The pressure of each cylinder can be adjusted separately and each cylinder has pressure protection device. The wind cooling can assure the machine to work continually.

Chip conveyer and coolant system: oil tank can be separated with chip conveyer, so the oil tank is convenient to clean, coolant system adopt big lift pump, the lift is 17m and the flow is 30L/min. so the processed area of the workpiece can be cooled sufficiently.

Lubrication: adopt centralized lubrication.

The machine has the alarm device and urgent stop button so as to protect the machine, the alarm will be displayed on the screen.

The electric cabinet is mated with air conditioner, and the protection class of the electric cabinet reach IP54.

MAIN TECHNICAL

| item | CK6156 | CK6156D | CK6163 | CK6180 | CK61100 | CK61125 | |

| max swing over bed | Φ560 | Φ560 | Φ630 | Φ800 | Φ1000 | Φ1250 | |

| max swing over slide | Φ400 | Φ400 | Φ500 | Φ630 | Φ700 | Φ800 | |

| Max workpiece length | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 1500/2000 /3000 | 1500/3000 | |

| Max turning workpiece length | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 750/1000/1500/ 2000/3000 | 1500/2000/ 3000 | 1500/3000 | |

| max turning diameter axial type | Φ320 | Φ320 | Φ500 | Φ600 | Φ700 | Φ800 | |

| max turning diameter plate type | Φ400 | Φ400 | Φ630 | Φ700 | Φ800 | Φ1000 | |

| mm spindle inner hole | Φ72 | Φ80 | Φ90 | Φ90 | Φ140 | Φ140 | |

| spindle inner hole taper | metric80 | metric100 | metric100 | metric120 | metric120 | metric160 | |

| spindle head nose | A2-8 | A2-8 | A2-8 | A2-11 | A2-11 | A2-15 | |

| item | CK6156 | CK6156D | CK6163 | CK6180 | CK61100 | CK61125 | |

| spindle rotating speed range | stepless r/min | 50-3000 - | - | - | - | - | - |

| two shift stepless | - | 50-1200 | 50~1000 | 50~800 | 50~800 | 50-650 | |

| kW main motor power | 15 | 15 | 22 | 30 | 37 | 37 | |

| (standard)mm chuck inner solid | Φ312 | Φ312 | Φ400 | Φ500 | Φ500 | Φ630 | |

| (optional )mm hydraulic chuck inner hollow | Φ312/55 | Φ312/55 | Φ400/75 | Φ500/75 | Φ500/85 | Φ630/100 | |

| mm Tailstock sleeve diameter | Φ110 | Φ110 | Φ120 | Φ120 | Φ170 | Φ200 | |

| mm Tailstock sleeve moving distance | 100 | 100 | 120 | 120 | 170 | 200 | |

| Tailstock sleeve inner hole taper | Morse5# | Morse5# | Morse6# | Morse6# | Morse6# | Morse6# | |

| Item | CK6156 | CK6156D | CK6163 | CK6180 | CK61100 | CK61125 | |

| m/min Rapid moving linear rolling guideway | 12/16 | - | - | - | - | 10/12 | |

| m/min the rectangular slide guideway | - | 10/10 | 10/10 | 10/10 | 10/10 | - | |

| mm max tool post travel | 230/800 | 230/800 | 325/800 | 360/800 | 415/1550 | 615/1550 | |

| (X/Z) Nm motor torque | 12/22 | 12/22 | 22/22 | 22/22 | 30/30 | 30/30 | |

| tool post capacity | 12 | 12 | 12 | 12 | 12 | 8 | |

| tool cross area mm | 25×25 | 25×25 | 32×32 | 32×32 | 32×32 | 32×32 | |

| mm tool inner diameter | Φ40 | Φ40 | Φ50 | Φ60 | Φ80 | Φ80 | |

| the machining accuracy | IT6 | IT6 | IT6 | IT6 | IT6 | IT6 | |

| Ra μm roughness | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| Item | CK6156 | CK6156D | CK6163 | CK6180 | CK61100 | CK61125 | |

| (X/Z) mm min set unit | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

| (X/Z) mm position accuracy | 0.01/0.012 | 0.01/0.012 | 0.012/0.015 | 0.012/0.015 | 0.012/0.020 | 0.012/ 0.015 | |

| (X/Z) mm repeat position accuracy | 0.006/0.008 | 0.006/0.008 | 0.007/0.01 | 0.007/0.01 | 0.007/0.012 | 0.010/ 0.012 | |

| net weight | 7000 | 7000 | 8000 | 8000 | 15000 | 20000 | |

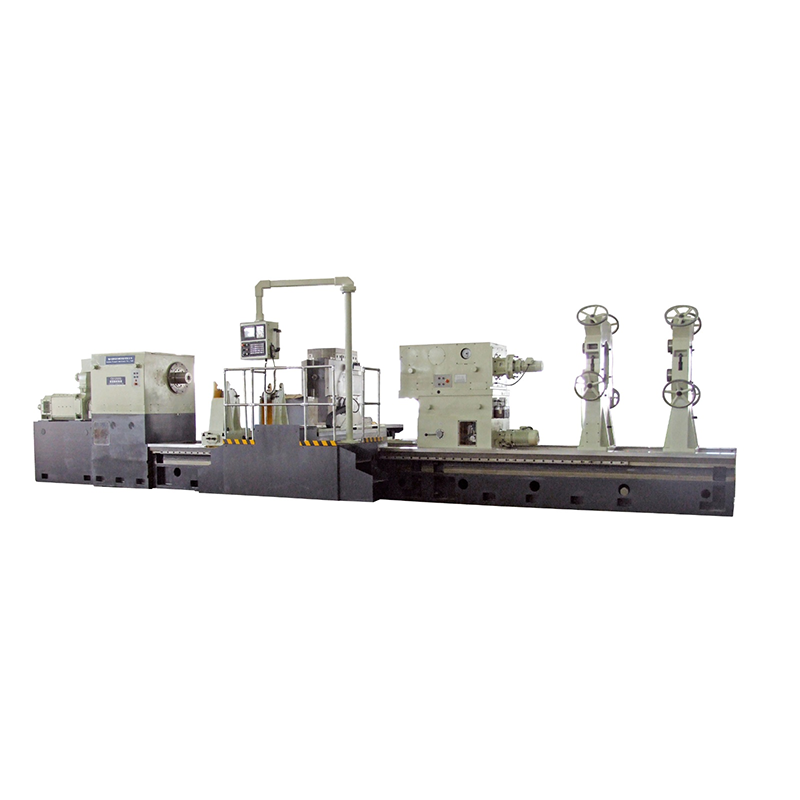

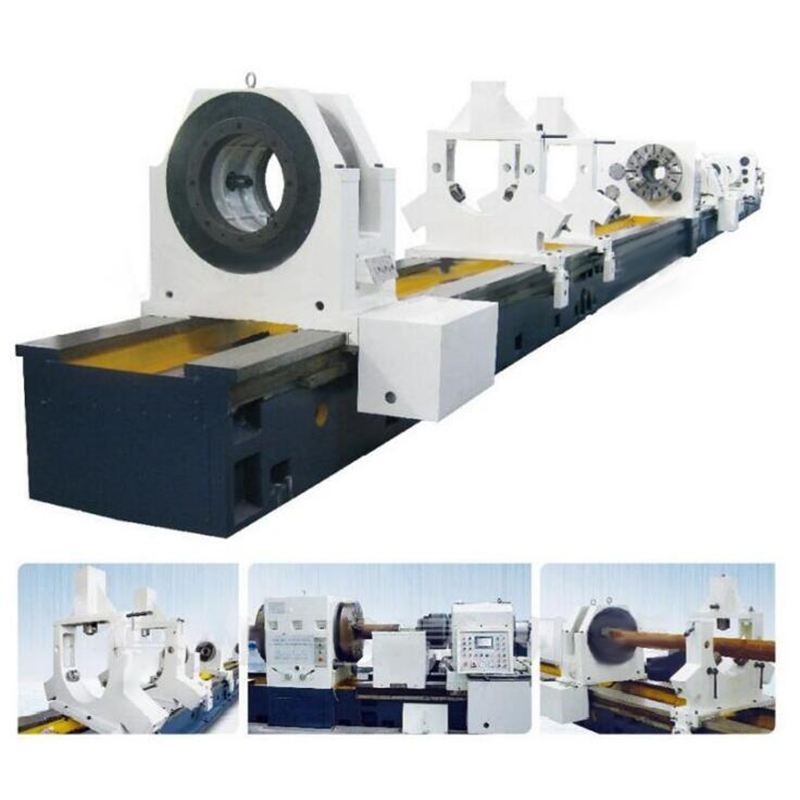

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to Always satisfy our customer requirements. We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Hot New Products Slant Bed - CK series CNC lathe with slant bed – Premach , The product will supply to all over the world, such as: Monaco, Swaziland, Jeddah, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that customer first and committed to helping customers expand their business, so that they become the Big Boss !

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!