High Quality Double Holes Tungsten Carbide Gun Drill for Deep Hole Drilling Machine

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for High Quality Double Holes Tungsten Carbide Gun Drill for Deep Hole Drilling Machine, We have been also the appointed OEM factory for several worlds’ famous merchandise brands. Welcome to speak to us for more negotiation and cooperation.

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for China Gun Drilling and Drill, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Function Description

By different design, this product can be equipped with one, two, three or four spindles, so that one, two, three or four workpieces can be processed at the same time.

Technical parameter

|

ZK2108 |

ZK2102 |

ZK2103 |

ZK2104 |

||

|

Capacity |

Drilling Dia. range |

Φ1-Φ8mm |

Φ3-Φ20mm |

Φ5-Φ40mm |

Φ5-Φ40mm |

|

Max. drilling depth |

10-300mm |

30-3000mm |

|||

|

Spindle |

Number of spindles |

1 |

1,2,3,4 |

1,2 |

1 |

|

Spindle speed |

350rpm |

350rpm |

150rpm |

150rpm |

|

|

Travel head with rotating drill |

Spindle speed |

3000-20000rpm |

500-8000rpm |

600-6000rpm |

200-7000rpm |

| Feed |

Feed speed range |

10-500mm/min |

10-350mm/min |

||

|

Rapid travel speed of travel head |

5000mm/min |

3000mm/min |

|||

|

Motor |

Motor power of travel head with rotating drill |

2.5KW |

4KW |

5.5KW |

7.5KW |

|

Motor power of headstock |

1.1KW |

2.2KW |

2.2KW |

3KW |

|

|

Feed motor torque (servo motor) |

4.7N.m |

7N.m |

8.34N.m |

11N.m |

|

|

Others |

Filtering precision of coolant |

8μm |

30μm |

||

|

Pressure of coolant |

1-18MPa |

1-10MPa |

|||

|

Max. flow of coolant |

20L/min |

100L/min |

100L/min |

150L/min |

|

|

CNC system |

KND, SIEMENS 802, FANUC etc. optional by user |

||||

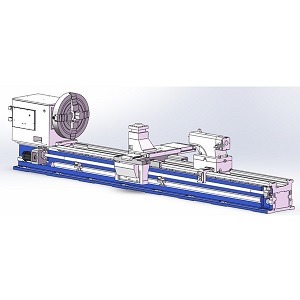

| Special deep hole drilling machine for petroleum drill collar TS21 series | ZS2110B | TS21 | ||

|

Working capacity |

Range of drilling Dia. | Φ30-Φ100mm | ||

| Max. drilling depth | 6-20m | |||

| Workpiece clamped Dia. range | Φ60-Φ300mm | |||

|

Spindle |

Center height from spindle center to bed | 600mm | 350mm | |

| Range of spindle speed | 18-290rpm, 9 gears | 42-670rpm, 12 gears | ||

|

Travel head with rotating drilling bar |

Spindle bore Dia. of travel head with rotating drilling bar | Φ120mm | Φ100mm | |

| Taper of spindle bore (travel head with rotating drilling bar) | Φ140mm, 1:20 | Φ140mm, 1:20 | ||

| Range of spindle speed (travel head with rotating drilling bar) | 25-410rpm, 12 kinds | 82-490rpm, 6 kinds | ||

|

Feed |

Feed speed range (infinite) | 0.5-450mm/min | ||

| Rapid travel speed of carriage | 2m/min | |||

|

Motors |

Main motor power | 45KW | 30KW | |

| Motor power of travel head with rotating drilling bar | 45KW | 30KW | ||

| Motor power of hydraulic pump | 1.5KW, n=144rpm. | |||

| Rapid travel motor power of carriage | 5.5KW | 4KW | ||

| Feed motor power | 7.5KW (servo motor) | |||

| Motor power of cooling pump | 5.5KW x 4 groups | |||

|

Others |

Guide way width | 1000mm | 650mm | |

| Rated pressure of cooling system | 2.5MPa | |||

| Flow of cooling system | 100,200,300,400L/min | |||

| Rated working pressure for hydraulic system | 6.3MPa | |||

|

Optional annular steady rest |

Φ60-330mm (for ZS2110B) | |||

| Φ60-260mm (for TS2120) | ||||

| Φ60-320mm (for TS2135) | ||||

Video

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for High Quality Double Holes Tungsten Carbide Gun Drill for Deep Hole Drilling Machine, We have been also the appointed OEM factory for several worlds’ famous merchandise brands. Welcome to speak to us for more negotiation and cooperation.

High Quality China Gun Drilling and Drill, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!