Welcome to our websites!

Featured

-

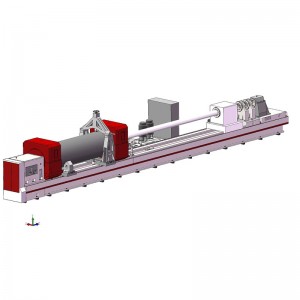

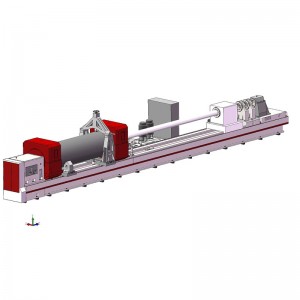

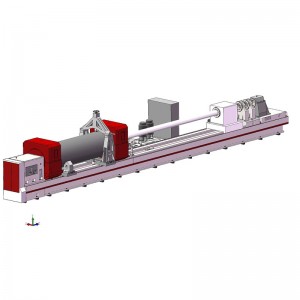

Ordinary Discount Cylinder Block Reboring - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

Cheap Price BTA Drilling Machine - ZK2302/ZK2303 Series 3D CNC Deep Hole Drilling Machine – Premach

Function Description It is widely used in water holes, injection pin holes and electric heating holes of plastic and rubber mold industry; Valves, distributors and pump bodies in hydraulic machinery industry; Engine block, oil supply system parts, transmission system parts, steering mechanism shell and steering shaft in automobile and tractor industries; Propulsion and landing gear of aerospace industry; Processing of geothermal exchange plate and other parts in generator industry. Technical ... -

Chinese Professional Hones - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

Wholesale Discount Small Deep Hole Drilling Machine - Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed – Premach

Video Display Function Description The grinding workpiece is made of carbon steel and various steels, including the hardened workpiece. If it’s cold drawn steel pipe, it can be directly performed strong honing. This series of deep hole powerful honing machine can process diameter range of 25-1000mm, and can process maximum depth up to 14000mm, which is divided into Jhc10, jhc20, jhc35, jhc50, jhc80, jhc100, etc. the machine is widely used in mold manufacturing, hydraulic machinery,... -

Hot Sale For Machine Boring Cylinder - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

Good Quality Multi Start Thread Cutting On Lathe - multi-purpose machine G1324,G1340 – Premach

Introduction G1324 / G1340 multi-purpose machine is a multi-functional composite machine tool, which has the functions of ordinary machine tool, drilling and milling machine, and can complete the machining of turning, drilling, milling, boring, tapping, metric and British threads. The G1324 / G1340 multi-purpose machine tool is composed of a machine bed, a headstock, a drilling and milling box, a workbench, a tool post, a tailstock, a feedbox, an apron and a vertical lifting mechanism. I... -

Discountable Price Cylinder Boring Bars - Large deep hole drilling and boring machine, cylinder boring machine T21100/T21160 – Premach

Function Description T21100/T21160 series is a deep-hole machining machine, which can support the process of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And for processing some large solid rods or some rods with expensive material, we usually us... -

Factory Low Price Cylinder Reboring Machine - Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed – Premach

Video Display Function Description The grinding workpiece is made of carbon steel and various steels, including the hardened workpiece. If it’s cold drawn steel pipe, it can be directly performed strong honing. This series of deep hole powerful honing machine can process diameter range of 25-1000mm, and can process maximum depth up to 14000mm, which is divided into Jhc10, jhc20, jhc35, jhc50, jhc80, jhc100, etc. the machine is widely used in mold manufacturing, hydraulic machinery,... -

Factory Best Selling Table Top Lathe Metal - double column vertical lathe C52 series – Premach

Function Description This machine is a double column vertical lathe, which is an advanced equipment with excellent performance, wide range of technology and high production efficiency. The machine is mainly applicable to high-speed steel and cemented carbide cutting tools, this series of double column vertical lathes are applicable to the motor, water turbine, aviation, mining machinery, metallurgy and general machinery industries, and can be used for rough and fine machining of inner a... -

OEM/ODM Factory Horizontal Engine Lathe - Q13 series pipe threading lathe, oil field & hollow spindle lathe – Premach

Features *Big spindle bore and double chuck allows clamp and process big diameter pipes. *Integral machine bed adopts high strength iron casting to realize high rigidity and precision. *Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance. *Equipped with taper guide bar device, this enables the machine to process taper threads. LATHE INTRODUCTION Q13 series pipe threading lathe mainly used for turning the internal and external threads, including metric and inch t... -

Factory Wholesale Cabinet Boring Machine - Deep Hole Turning and Boring Machine TCS2150 – Premach

Function Description The machine is installed with work headstock and travel head with rotating drilling/boring rod, both workpiece and tool can rotate, and the cutting tool can also be fixed, only feed. In addition, this machine is also installed a toolpost like that of the lathe, so that the machine adds the function of turning outer circle on the basis of deep hole drilling and boring machine. The machine is a series of products, and can also provide various modified products accordin... -

Good Wholesale Vendors Boring Head For Drill Press - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r...