Welcome to our websites!

Featured

-

Hot New Products Drill Press Boring Tool - Hones, CNC Deep Hole Honing Machine 2mk2125/2mk2135/2mk2150 Series With Iron Casting Bed – Premach

Video Display Function Description This machine is mated with CNC system, AC servo moto, travel head with rotating honing rod adopts stepless speed. It is mated with high accuracy racks and gears to realize the reciprocating of honing head and it can control the honing position too. Mated with double linear guide way, so it has long life and high accuracy. The honing head adopt hydraulic constant pressure expanding. Sand blades always maintain constant pressure to be sure the round... -

New Fashion Design For Boring In Drilling Machine - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

Discountable Price Small Boring Machine - TK2620 Series CNC Six Coordinates Deep Hole Drilling Machine – Premach

Function Description The machine tool is controlled by the CNC control system, which can control six servo coordinate axes at the same time. It can drill both row holes and coordinate holes. It can drill through the holes at one time, or turn around 180 degrees to drill holes. It has both single action performance and automatic circulation performance. Therefore, it can meet the requirements of small batch production and processing as well as the requirements of large batch production an... -

8 Year Exporter Conventional Turning Machine - CH61200L CNC turning center with C axis – Premach

Brief instruction This machine is mated with C axis, feed X and Z axis, three axis can be linkage and move together with multi-function and high cutting efficiency. Mated with SIEMENS 828D CNC system. Two gears of spindle speed, and stepless speed within gears, hydraulic gear shift, consistent line speed cutting. Main spindle motor is SIEMENS 37KW A.C. servo motor, decrease speed and increase torque by gears, spindle speed is 5-200rpm. C axis is indexed by high precision AC servo moto... -

Wholesale Discount Cylinder Boring Machine Motorcycle - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

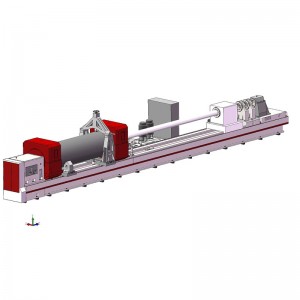

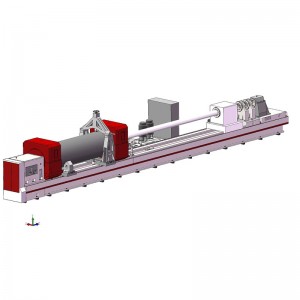

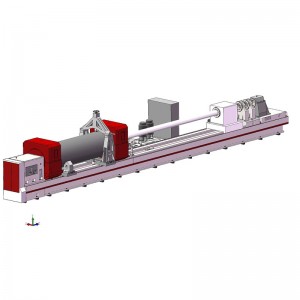

Factory Outlets For Cnc Deep Hole Drilling Machine - Deep Hole Turning and Boring Machine TCS2150 – Premach

Function Description The machine is installed with work headstock and travel head with rotating drilling/boring rod, both workpiece and tool can rotate, and the cutting tool can also be fixed, only feed. In addition, this machine is also installed a toolpost like that of the lathe, so that the machine adds the function of turning outer circle on the basis of deep hole drilling and boring machine. The machine is a series of products, and can also provide various modified products accordin... -

Factory Low Price Small Engine Boring Tool - Hones, CNC Deep Hole Honing Machine 2mk2125/2mk2135/2mk2150 Series With Iron Casting Bed – Premach

Video Display Function Description This machine is mated with CNC system, AC servo moto, travel head with rotating honing rod adopts stepless speed. It is mated with high accuracy racks and gears to realize the reciprocating of honing head and it can control the honing position too. Mated with double linear guide way, so it has long life and high accuracy. The honing head adopt hydraulic constant pressure expanding. Sand blades always maintain constant pressure to be sure the round... -

Good Quality Gun Barrel Boring Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

Factory Directly Supply Small Bench Lathe - slant bed CNC pipe threading lathe,oil field & hollow spindle lathe YJP-YPT series – Premach

Features *Big spindle bore and double chuck to ensure process big diameter pipe. *One-piece bed adopts high strength iron to ensure rigidity and precision. *Ultrasonic frequecncy quenched guide ways ensure good wear-resistance. *Carriage and guide way contact surface use Turcite B to maintain accuracy. *Double pneumatic chucks ensure hold workpiece stable and efficiency. LATHE INTRODUCTION Slant bed CNC pipe threading lathe series is the new type automatic lathe with high precision and high e... -

Big Discount Small Bore Drilling Machine - ZK21 Series CNC Gundrill Machine – Premach

Function Description By different design, this product can be equipped with one, two, three or four spindles, so that one, two, three or four workpieces can be processed at the same time. Technical parameter ZK2108 ZK2102 ZK2103 ZK2104 Capacity Drilling Dia. range Φ1-Φ8mm Φ3-Φ20mm Φ5-Φ40mm Φ5-Φ40mm Max. drilling depth 10-300mm 30-3000mm Spindle Number of spindles 1 1,2,3,4 1,2 1 Spindle speed 350rpm 350rpm 150rpm 150rpm ... -

Fast Delivery Boring Rod - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

New Arrival China Turning And Boring - ZK2303A Series CNC Tube-Plate Drilling Machine – Premach

Function Description The machine tool includes both BTA Deep hole drill (internal metal chip removal) and gun drill (external metal chip removal). Through one-time drilling, the machining accuracy and surface roughness that can only be guaranteed by drilling, expanding and reaming processes can be achieved. The mutual conversion between BTA and gun drill drilling is realized by replacing the corresponding components. The machine tool has three independent drilling systems. The three dril...