Welcome to our websites!

Featured

-

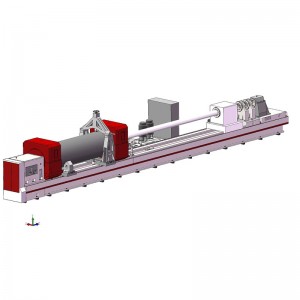

Popular Design For Precision Gun Drilling - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

Hot Sale Vtl Machine - Single column vertical lathe C516A/ C518A series – Premach

Function Description This series of machine is a new generation of vertical lathes designed and developed by our company. It is an advanced equipment integrating machinery and electricity. It draws on and absorbs brand-new design concepts and advanced design and manufacturing technologies, adopts CAD Optimization design methods, configures advanced functional components at home and abroad, and realizes strong cutting, high dynamic and static stiffness, high accuracy, heavy load, high eff... -

Wholesale Price Number Of Spindle - Deep Hole Drilling And Boring Machine, Cylinder drilling and boring machine TQ2180 – Premach

Video Display Function Description TQ2180 is a cylinder driling and boring machine, which can perform the function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And we use extra metal chip removal technique for trepanning with professiona... -

Factory Directly Cylinder Head Boring Machine - Deep Hole Drilling And Boring Machine, Cylinder drilling and boring machine TQ2180 – Premach

Video Display Function Description TQ2180 is a cylinder driling and boring machine, which can perform the function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And we use extra metal chip removal technique for trepanning with professiona... -

OEM Customized Horizontal Boring Under Driveway - Deep Hole SRB Machine TGK Series – Premach

Video Display Function Description When processing. the workpiece is fixed and the cutting tool is rotated. Adopting the combined technology of skiving and roller burnishing, the machine gives a good solution for the severe deviation in rough processing of hot roller steel pipe, and the inferior straightness in fine processing of cold drawn steel tube. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up t... -

Personlized Products Horizontal Cnc Lathe - CNC pipe threading lathe, oil field & hollow spindle lathe Q1313-1319-1322 series – Premach

Features *Big spindle bore and double chuck allows clamp and process big diameter pipes. *Integral machine bed adopts high strength iron casting to realize high rigidity and precision. *Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance. *Equipped with taper guide bar device, this enables the machine to process taper threads. LATHE INTRODUCTION This series CNC pipe threading lathe is mainly used for processing the internal and external pipe threads, including m... -

Good Quality Variable Speed Bench Lathe - Four guide ways heavy duty horizontal CNC lathe CK61250F series – Premach

Product characteristic The ck61xxf series is an improved series of heavy-duty horizontal CNC lathes developed by our company based on our long-term experience in horizontal lathe production and adopting internationally advanced design means and manufacturing technology. It implements the latest national accuracy standards and is meticulously designed by integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool product... -

Good Quality Gun Barrel Boring Machine - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

Factory Source Boring Bar Cutters - Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed – Premach

Video Display Function Description The grinding workpiece is made of carbon steel and various steels, including the hardened workpiece. If it’s cold drawn steel pipe, it can be directly performed strong honing. This series of deep hole powerful honing machine can process diameter range of 25-1000mm, and can process maximum depth up to 14000mm, which is divided into Jhc10, jhc20, jhc35, jhc50, jhc80, jhc100, etc. the machine is widely used in mold manufacturing, hydraulic machinery,... -

Europe Style For Boring Machine Mini - Deep Hole Turning and Boring Machine TCS2150 – Premach

Function Description The machine is installed with work headstock and travel head with rotating drilling/boring rod, both workpiece and tool can rotate, and the cutting tool can also be fixed, only feed. In addition, this machine is also installed a toolpost like that of the lathe, so that the machine adds the function of turning outer circle on the basis of deep hole drilling and boring machine. The machine is a series of products, and can also provide various modified products accordin... -

Competitive Price For FANUC - Four guide ways heavy duty horizontal CNC lathe CK61250F series – Premach

Product characteristic The ck61xxf series is an improved series of heavy-duty horizontal CNC lathes developed by our company based on our long-term experience in horizontal lathe production and adopting internationally advanced design means and manufacturing technology. It implements the latest national accuracy standards and is meticulously designed by integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool product... -

High Quality Diamond Boring Machine - ZK2303A Series CNC Tube-Plate Drilling Machine – Premach

Function Description The machine tool includes both BTA Deep hole drill (internal metal chip removal) and gun drill (external metal chip removal). Through one-time drilling, the machining accuracy and surface roughness that can only be guaranteed by drilling, expanding and reaming processes can be achieved. The mutual conversion between BTA and gun drill drilling is realized by replacing the corresponding components. The machine tool has three independent drilling systems. The three dril...