Welcome to our websites!

Featured

-

Wholesale Price China Drilling Diameter - ZK2302/ZK2303 Series 3D CNC Deep Hole Drilling Machine – Premach

Function Description It is widely used in water holes, injection pin holes and electric heating holes of plastic and rubber mold industry; Valves, distributors and pump bodies in hydraulic machinery industry; Engine block, oil supply system parts, transmission system parts, steering mechanism shell and steering shaft in automobile and tractor industries; Propulsion and landing gear of aerospace industry; Processing of geothermal exchange plate and other parts in generator industry. Technical ... -

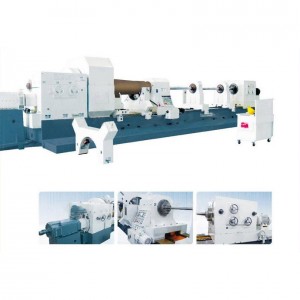

Factory Promotional Spindle Boring Machine - Deep hole drilling machine special for petroleum drill coller ZSK21 series – Premach

Introduction ZSK2110B CNC deep-hole drilling machine adopt BTA chip removal to drill small diameter deep-hole workpieces, is very suitable for petroleum drill collar workpiece. The biggest characteristic of this machine is that: the front end of workpiece which near to the oil pressure head is clamped by double chucks and the rear end is clamped by annular steady rest. The top locking of workpiece and the fixation of oil pressure head are controlled by hydraulic system, safe and practica... -

Wholesale Price Number Of Spindle - Deep Hole SRB Machine TGK Series – Premach

Video Display Function Description When processing. the workpiece is fixed and the cutting tool is rotated. Adopting the combined technology of skiving and roller burnishing, the machine gives a good solution for the severe deviation in rough processing of hot roller steel pipe, and the inferior straightness in fine processing of cold drawn steel tube. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up t... -

High Quality Vintage Bench Lathe - CNC end face turning lathe – Premach

Protection device of machine rotation parts The pull and push device is installed on the Machine rotation part (such as chuck and Motor) to prevent the fall off of workpiece Due to centrifugal force, and ensure the machine and operator’s safety. This design meets with safety standard of machine design. Center design of sliding platec srew+flat guide way design+dovetail rail positioning dual axis of machine are all driven by high precision ground ball screw which are all centr... -

One Of Hottest For Boring Machine Boring Machine - ZK2302/ZK2303 Series 3D CNC Deep Hole Drilling Machine – Premach

Function Description It is widely used in water holes, injection pin holes and electric heating holes of plastic and rubber mold industry; Valves, distributors and pump bodies in hydraulic machinery industry; Engine block, oil supply system parts, transmission system parts, steering mechanism shell and steering shaft in automobile and tractor industries; Propulsion and landing gear of aerospace industry; Processing of geothermal exchange plate and other parts in generator industry. Technical ... -

Competitive Price For Cnc Boring Bar Sleeves - Deep Hole SRB Machine TGK Series – Premach

Video Display Function Description When processing. the workpiece is fixed and the cutting tool is rotated. Adopting the combined technology of skiving and roller burnishing, the machine gives a good solution for the severe deviation in rough processing of hot roller steel pipe, and the inferior straightness in fine processing of cold drawn steel tube. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up t... -

2021 China New Design Drilling And Boring - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

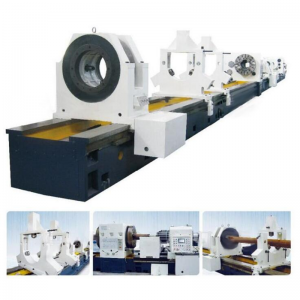

Discountable Price Bench Top Lathe Machine - Heavy duty horizontal CNC lathe CG series – Premach

Product characteristic This series of heavy-duty horizontal lathes is a kind of well-designed and multi-disciplinary lathe integrating electrical, automatic control, hydraulic control and modern mechanical design, which is based on the our company’s long-term experience in the production of horizontal lathe. has absorbed the advanced technology of the international era, adopted the international advanced design means and manufacturing technology, such as three-dimensional modeling, simul... -

Big Discount Small Bore Drilling Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

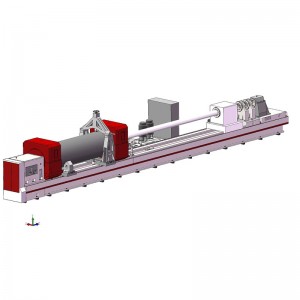

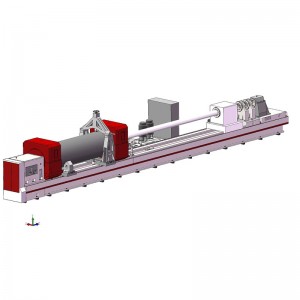

Online Exporter Pipeline Boring Machine - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

2021 Good Quality Six Axis Drilling Machine - Cylinder drilling and boring machine, Deep Hole Drilling And Boring Machine T2180/T2280 – Premach

Video Display Function Description T2180 is a deep-hole machining machine, which can support the process of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And we used extra metal chip removal technique for trepanning which need professional t... -

Best Price On Largest Tunnel Boring Machine - Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed – Premach

Video Display Function Description The grinding workpiece is made of carbon steel and various steels, including the hardened workpiece. If it’s cold drawn steel pipe, it can be directly performed strong honing. This series of deep hole powerful honing machine can process diameter range of 25-1000mm, and can process maximum depth up to 14000mm, which is divided into Jhc10, jhc20, jhc35, jhc50, jhc80, jhc100, etc. the machine is widely used in mold manufacturing, hydraulic machinery,...