Welcome to our websites!

Featured

-

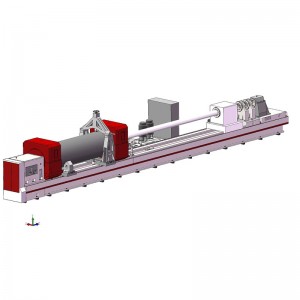

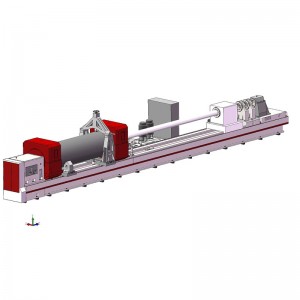

Cheap PriceList For Hole Drilling Machine - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r... -

Hot Sale For Boring In Mechanical Engineering - Deep Hole SRB Machine TGK Series – Premach

Video Display Function Description When processing. the workpiece is fixed and the cutting tool is rotated. Adopting the combined technology of skiving and roller burnishing, the machine gives a good solution for the severe deviation in rough processing of hot roller steel pipe, and the inferior straightness in fine processing of cold drawn steel tube. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up t... -

Trending Products Boring Spindle - ZK21 Series CNC Gundrill Machine – Premach

Function Description By different design, this product can be equipped with one, two, three or four spindles, so that one, two, three or four workpieces can be processed at the same time. Technical parameter ZK2108 ZK2102 ZK2103 ZK2104 Capacity Drilling Dia. range Φ1-Φ8mm Φ3-Φ20mm Φ5-Φ40mm Φ5-Φ40mm Max. drilling depth 10-300mm 30-3000mm Spindle Number of spindles 1 1,2,3,4 1,2 1 Spindle speed 350rpm 350rpm 150rpm 150rpm ... -

OEM China Horizontal Boring Machine For Pipeline - Deep Hole Turning and Boring Machine TCS2150 – Premach

Function Description The machine is installed with work headstock and travel head with rotating drilling/boring rod, both workpiece and tool can rotate, and the cutting tool can also be fixed, only feed. In addition, this machine is also installed a toolpost like that of the lathe, so that the machine adds the function of turning outer circle on the basis of deep hole drilling and boring machine. The machine is a series of products, and can also provide various modified products accordin... -

Hot-Selling Double Chuck Lathe - bench lathe CZ1340A CZ1440A – Premach

Features *brake equipment can make spindle stopped very quickly, but motor not stop for better protection *Supersonic frequency hardened bed ways; *Precision roller bearing for spindle; *High quality steel,ground and hardened gear inside headstock; * Easy and fast operating gearbox; *Enough strong power motor; *ASA D4 camlock spindle nose; *Various threads cutting functions available Standard Accs *3-jaw chuck, *Follow rest&Steady rest, *Screws, *Oil gun, *Centre & Centre sleeve, *Too... -

OEM Customized Big Boring Machine - ZK2302/ZK2303 Series 3D CNC Deep Hole Drilling Machine – Premach

Function Description It is widely used in water holes, injection pin holes and electric heating holes of plastic and rubber mold industry; Valves, distributors and pump bodies in hydraulic machinery industry; Engine block, oil supply system parts, transmission system parts, steering mechanism shell and steering shaft in automobile and tractor industries; Propulsion and landing gear of aerospace industry; Processing of geothermal exchange plate and other parts in generator industry. Technical ... -

High Quality For Automatic Lathe - horizontal engine conventional lathe CW6163E,CW6180E,CW61100E,CE61200E – Premach

Use and characteristics This machine tool is a universal general-purpose lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The machine body has high rigidity, and the apron, tool post and saddle can move quickly. This lathe has the characteristics of strong rigidity, high efficienc... -

2021 Latest Design Boring Machine Head - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

Factory Low Price Cylinder Reboring Machine - Heavy Duty Deep Hole SRB Machine TGK50/TGK63 Series – Premach

Video Display Function Description TGK CNC boring, skiving and roller burnishing machine has the smart and simple CNC operation system with high efficiency and stable performance, using environmental protection measures against oil splash and leakage. It is mainly used for the compound process of boring and roller burnishing for hydraulic cylinder parts. The hole tolerance is up to IT7-8, the surface roughness is up to Ra0.2-0.4μm. TGK series machines adopt Siemens 808 CNC system (... -

Discountable Price Cylinder Boring Bars - Deep Hole Pull Boring Machine, Cylinder pull boring machine TLS2210A/TLS2220B – Premach

Video Display Function Description According to the processing requirement, the machine can also adopt the mod of the workpiece is fixed, the cutting tool rotates and feeds, and the cutting coolant enters the cutting area through the oil pressure head to cool and lubricate the cutting area and take away the metal chips. Machining accuracy: When pull boring: hole diameter accuracy is IT8-10. Surface roughness (related to cutting tools): Ra3.2. Machining efficiency of machine TLS2220... -

Quality Inspection For Collet Boring Machine - Large deep hole drilling and boring machine, cylinder boring machine T21100/T21160 – Premach

Function Description T21100/T21160 series is a deep-hole machining machine, which can support the process of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal is used while drilling and forward metal chips removal inside boring rod by cutting liquid is for boring. And for processing some large solid rods or some rods with expensive material, we usually us... -

Europe Style For Metal Lathe Boring Bar - TMK2280 Deep Hole Cylinder Boring And Honing Compound Machine – Premach

Function Description 2.1 Boring By means of push boring, the cutting oil enters the inner hole of the tool tube from the end of it, and then reaches the cutting edge. One end of the workpiece is supported by a manual four jaw chuck, the other end is supported by a steady rest, and the middle of the workpiece is supported by a support jack. The chip removal device is placed at the left and right ends of the workpiece to send the chip into the chip receiving tank, and the cutting oil directly r...