Featured Products

-

Fixed Competitive Price CE Certificated Single Column Manual Vertical Turret Lathe Machine for Sale

This machine is a professional product designed according to the needs of motor, valve, water pump, bearing, automobile and other industries. This machine is suitable for rough and finish machining of inner and outer cylindrical surfaces, end faces, grooves, etc. of ferrous metals, non-ferrous metals and some non-metallic parts with high-speed steel and hardware alloy tools.

-

Factory supplied Extremely Cost Effective Qk1313 Special Machine CNC Pipe Threading Lathe

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

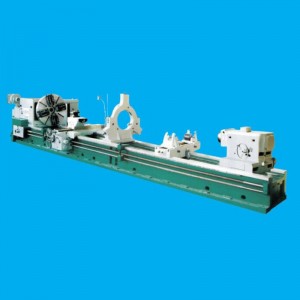

OEM/ODM Manufacturer Dmtg CDS6150b Conventional Engine Lathe Machine Horizontal Manual Lathe Torno

The lathe bed is of an integral floor type structure. It is integrally cast. After casting and rough machining, it is subject to aging treatment to ensure the structural rigidity of the whole machine. The guide way surface is subject to medium frequency quenching, the hardness is not less than HRC52, the hardening depth is not less than 3mm, and the stability of the whole machine is good.

The reasonable structure design ensures that the lathe has sufficient static and dynamic rigidity. The advanced technology ensures that the machine has good quality, low noise and small vibration.

Beautiful appearance, combined with ergonomic principles, easy adjustment of workpieces, easy operation and maintenance.

The main parts such as the bed, headstock, carriage and tailstock are made of high-quality resin sand castings. After natural aging and artificial aging, the main parts of the machine are guaranteed to have low deformation and high stability.

The spindle adopts a three support structure, with reasonable span, low noise, low heat generation and good accuracy retention.

The spindle has a wide speed range, stable operation, low temperature rise and good accuracy retention.

The main transmission gear is hardened and ground to ensure its high accuracy, smooth operation and low noise.

High cutting power and high processing efficiency.

-

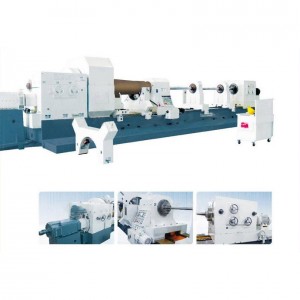

OEM Customized CNC Pipe Threading Lathe (CNC Oil Country lathe QK1327 QK1332)

QK1327 and QK1363 series machine tools are horizontal flat bed CNC hollow spindle lathes with semi closed loop control. Two linkage control axes, Z-axis and X-axis use ball screw pairs and AC servo motors to achieve longitudinal and lateral movement, with good positioning accuracy and repeated positioning accuracy.

This machine tool is designed and manufactured for thread processing of all kinds of pipes in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. This machine tool can also process rotary parts as a normal conventional lathe. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

-

Cheap PriceList for Conventional Horizontal Metal Lathe Machine C6140 Manual Turning Lathe

This series of engine conventional lathes has been continuously updated and improved by our company for more than 40 years, after absorption of advanced design and manufacturing technologies at home and abroad, and after use of users in aerospace, railway, valve and other industries, the practice has proved that the large horizontal lathes produced by our company have reached the advanced level in China.

The technical features of this series of lathes are as follows: first, the basic parts, the spindle tailstock quill, etc. have passed the optimization design and fine processing, with high precision and life; second, the key components, such as the spindle bearings and the main electrical components, are all famous brands at home and abroad.

-

Factory Promotional Deep Hole Drilling Machine for Precision Cylinder (Deep Hole Boring Machine)

This series of machine is suitable for drilling, boring and rolling the center hole of shaft parts (hydraulic cylinder, air cylinder, steel pipe, drilling tool, etc.). Drilling adopts BTA processing method; PLC control system and touch screen; The rotary seal of the oil pressure head adopts the newly designed oil leakage proof structure, and can effectively absorb the vibration of the bar of cutting tool; The cooling system is equipped with an oil tank on the ground.

-

Factory Selling Heavy Duty CNC Pipe Lathe Machine Qk1319 Pipe Threading Lathe CNC

This series of machine tools are mainly used for pipe thread processing, and can cut metric and inch cylindrical and conical pipe threads. It is suitable for processing tubing, casing, drill pipe, etc. in petroleum, metallurgy, chemical, hydropower, geology and other departments.

Mated with CNC system, with high control precision and good reliability. The machine tool can also adopt PLC controller, which improves the reliability and control flexibility of the machine tool.

-

High reputation Deep Drilling Machine High Quality Delicated Hardware Open-Sided Precision Gun Drilling Machine (DH-1310R)

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

China OEM Ztk100X160/120 CNC Heavy Duty Deep-Hole Drilling and Boring Machine

T2180 is a big cylinder drilling and boring machine, which can perform the processing function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal method is used for drilling and forward metal chips removal inside boring rod by cutting liquid for boring.

-

OEM Manufacturer Fanuc CNC Machine, CNC Turning Machine, Fanuc CNC Lathe Machine, CNC Lathe with Fanuc, CNC Lathe with Fanuc Control EL52L

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

Renewable Design for Qk1335 Automatic Oil Country Pipe Cutting Pipe Threading CNC Lathe

*Big spindle bore and double chuck to ensure process big diameter pipe. *One-piece bed adopts high strength iron to ensure rigidity and precision. *Ultrasonic frequecncy quenched guide ways ensure good wear-resistance. *Carriage and guide way contact surface use Turcite B to maintain accuracy.

-

OEM Manufacturer Custom CNC Deep Hole Solid Drilling and Hollow Boring Machine

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.