Featured Products

-

100% Original Ck5120 CNC Single Column Universal Vertical Turning Lathe Machine Vtl Series Vertical Big Travel Fanuc System

This machine is a professional product designed according to the needs of motor, valve, water pump, bearing, automobile and other industries. This machine is suitable for rough and finish machining of inner and outer cylindrical surfaces, end faces, grooves, etc. of ferrous metals, non-ferrous metals and some non-metallic parts with high-speed steel and hardware alloy tools.

-

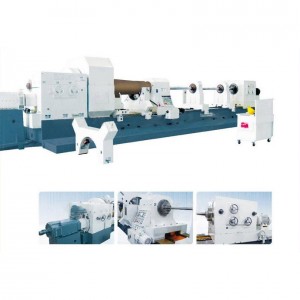

Wholesale OEM/ODM Professional Pipe Threading CNC Lathe with 50 Years Experience (CK6163)

*Big spindle bore and double chuck allows clamp and process big diameter pipes. *Integral machine bed adopts high strength iron casting to realize high rigidity and precision. *Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance. *Equipped with taper guide bar device, this enables the machine to process taper threads.

-

Supply OEM Precision Carbide Deep Hole Gun Drill Bit

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

2019 New Style Heavy Duty Big Bore Lathe Cw62125c/8000

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for 2019 New Style Heavy Duty Big Bore Lathe Cw62125c/8000, We aim at Ongoing system innovation, management innovation, elite innovation and industry innovation, give full play on the overall advantages, and continuously make improvements to service high-quality. We purpose to understand high quality disfigurement with the output and supply the top serv... -

Factory Price Auto Feed Lathe Qk1327 CNC Pipe Threading Lathe for Oil Country

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

OEM Factory for Stem V6 3.0t Crankshaft Ea837 VW3.0 V6 Tfsi OEM 06e105101AA for Audi VW

“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for OEM Factory for Stem V6 3.0t Crankshaft Ea837 VW3.0 V6 Tfsi OEM 06e105101AA for Audi VW, We adhere to your tenet of “Services of Standardization, to satisfy Customers’ Demands”. “Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception... -

Factory For 304 Big Diameter Cylinder Tube Honed Stainless Steel Tube

T2180 is a big cylinder drilling and boring machine, which can perform the processing function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal method is used for drilling and forward metal chips removal inside boring rod by cutting liquid for boring.

-

Hot Selling for Heavy Duty Torno Horizontal Turning Flat-Bed CNC Lathe Ck-6185

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Hot Selling for Heavy Duty Torno Horizontal Turning Flat-Bed CNC Lathe Ck-6185, We will do our best to meet or exceed customers’ requirements with quality products, advanced concept, and efficient and timely service. We welcome all customers. carry on to further improve, to guarante... -

Reliable Supplier Cdk6150 Heavy Duty Big Bore Pipe Threading CNC Turning Milling Lathe

*Big spindle bore and double chuck allows clamp and process big diameter pipes. *Integral machine bed adopts high strength iron casting to realize high rigidity and precision. *Ultrasonic frequecncy quenched guide ways are hard enough for good wear-resistance. *Equipped with taper guide bar device, this enables the machine to process taper threads.

-

Newly Arrival CS6266C Strong Conventional Horizontal Large Spindle Bore Lathe Machine

The lathe bed is of an integral floor type structure. It is integrally cast. After casting and rough machining, it is subject to aging treatment to ensure the structural rigidity of the whole machine. The guide way surface is subject to medium frequency quenching, the hardness is not less than HRC52, the hardening depth is not less than 3mm, and the stability of the whole machine is good.

The reasonable structure design ensures that the lathe has sufficient static and dynamic rigidity. The advanced technology ensures that the machine has good quality, low noise and small vibration.

Beautiful appearance, combined with ergonomic principles, easy adjustment of workpieces, easy operation and maintenance.

The main parts such as the bed, headstock, carriage and tailstock are made of high-quality resin sand castings. After natural aging and artificial aging, the main parts of the machine are guaranteed to have low deformation and high stability.

The spindle adopts a three support structure, with reasonable span, low noise, low heat generation and good accuracy retention.

The spindle has a wide speed range, stable operation, low temperature rise and good accuracy retention.

The main transmission gear is hardened and ground to ensure its high accuracy, smooth operation and low noise.

High cutting power and high processing efficiency.

-

High Quality Ronix Model Ra-8016 Newest 60-100psi Pressure Hand Tool Air Nailer Gun Drill

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

Cheap price CNC Gun Drill Machinery with Milling Capacity and Fanuc for Mould Making (ZJA13-1610)

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.