Featured Products

-

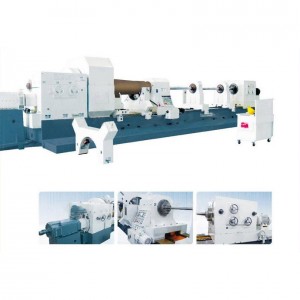

Low MOQ for Oil Pipe Lathe (CNC Pipe Threading Lathe Machine QK1343)

This machine tool is designed and manufactured for thread processing of oil pipe, drill pipe and casing in petroleum, chemical and metallurgical industries. It can turn all kinds of internal and external threads (metric, inch and taper pipe threads) accurately through the automatic control of CNC system. It is especially suitable for thread processing with mass production. This machine can also process rotary parts. For example, rough and finish machining of internal and external cylindrical surfaces, conical surfaces, circular surfaces, and medium and small batches of shaft and disk parts. It has the characteristics of high automation, simple programming and high machining accuracy.

The machine tool has two linkage control axes, semi closed loop control. The Z-axis and X-axis use ball screw pairs and AC servo motors to achieve vertical and horizontal movement, with good positioning accuracy and repeated positioning accuracy.

-

High Quality for Ztk100X160/120 CNC Heavy Duty Deep-Hole Drilling and Boring Machine

T2163 is special equipment for machining deep cylindrical hole of workpieces. It can be perfectly suited for drilling, boring and trepanning through holes, blind and step hole in workpiece: such as, spindle of various kinds of machines, many kinds of hydraulic cylinders and cylinders. It can perform not only drilling and boring, but also rolling and trepanning. The method of the internal-removal (BTA) chip is adopted in drilling, and external metal chips removal is used for boring and trepanning.

-

OEM Supply Cemented Carbide Gun Drill Bit Blanks

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

OEM Customized End Face and Precision CNC Lathe (CK64160E)

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

Wholesale ODM Semi-Automatic High Precision Brake Lathe Horizontal Lathe Bed Big Swing Gap-Bed Conventional Metal Lathe (CA6150)

This machine tool is a universal conventional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

Low MOQ for Ck6150 Hard Guide Rail High Precision CNC Bench Lathe

* Ultra audio frequency quenching bed guide way;

* Spindle is mated with precision roller bearings;

* Gears inside headstock were hardened and ground.

* Gearbox is easy operating.

* Motor is strong enough;

* Spindle nose is ASA D4 camlock type;

* Various threads cutting functions available.All our bench lathes have to go through three separate checks throughout the whole manufacturing process: iron casting and all kinds of purchased and self-made parts, each machincal part for machine assembly and accuracy inspection of finished product, We control quality from raw materials, we always select the best quality raw materials, for example, resin sand iron casting with HT300 materal and famous brand electric elements, and we have an quality inspector for each process, quality is always our top concerned. we welcome all the customers from all over the world for cooperation.

-

Chinese wholesale Diamond and CBN Hone Single Pass Honing

This deep hole powerful honing machine is equipped with PLC controller or CNC system (optional), linear rolling guide way, AC servo motor, grinding rod adopts stepless speed regulation, stable commutation, convenient speed regulation, easy to ensure the accuracy of hole size, and reduce labor intensity. In the honing process, the sand rod and the workpiece always maintain constant pressure, so that the sand rod can be strongly ground. It ensures the high efficiency of deep hole machining, and is suitable for rough and fine honing of general cylindrical deep hole parts. This type of machine tool can also be used for partial honing to correct the taper and ellipticity of parts and the partial hole error.

-

High reputation CNC Horizontal Double-Spindle Deep Hole High-Speed Drilling Machine 4000mm*750mm

T2180 is a big cylinder drilling and boring machine, which can perform the processing function of drilling, boring and trepanning the large workpiece with big diameter. While working, the workpiece rotates slowly and the cutting tool rotates in high speed and feed. BTA chip removal method is used for drilling and forward metal chips removal inside boring rod by cutting liquid for boring.

-

Leading Manufacturer for Deep Hole Honing Machine for Tubes

2MK2125, 2MK2135 and 2MK2150 series CNC deep hole honing machine adopt iron casting bed, is suitable for honing and burnishing cylindrical deep-hole parts, such as various hydraulic cylinders. It can also perform honing and burnishing step holes, and the hole diameter accuracy after honing can reach IT8-IT9, the surface roughness can reach Ra0.2-Ra0.4μm. it can also repair the taper, ellipticity and partial hole tolerance with the partial honing. It can directly perform high efficiency honing of cold drawing steel pipes. This series deep hole honing machine is an ideal machine for deep-hole machining with high accuracy and high efficiency.

-

Factory Directly supply 800-11p-12A-D63 BTA Deep Hole Drill Head

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Factory Directly supply 800-11p-12A-D63 BTA Deep Hole Drill Head, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishm... -

Cheap price Multi Spindle Wood Boring and Drilling Machine

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance. The machine tool has the functions of drilling, boring, rolling and trepanning. Suitable for machining the center hole of shaft parts. PLC control system and touch screen are adopted for simple operation; The above ground oil tank is adopted for the cooling system.

-

Super Purchasing for Ncsd-600 Center Hole Gun Drilling Machine

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.