Featured Products

-

China Cheap price Dx-35 Portable Drill Bit Magnetic Drilling Machine

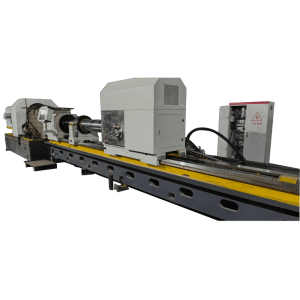

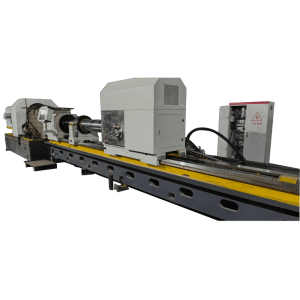

T2150 deep hole drilling and boring machine is the heavy machine tool. The workpiece is positioned by a taper plate while boring, and that is clamped by a three-jaw chuck during drilling. The oil pressure head adopts the spindle structure, which greatly improves the bearing performance and the rotation accuracy. The guide way adopts a high rigid structure suitable for deep hole machining, with large bearing capacity and good guiding accuracy; The guide way is quenched and has high wear resistance.

-

High Performance China Customized Small Diameter Thin Wall Brass Copper Pipe with Smooth Surface

T2163 is special equipment for machining deep cylindrical hole of workpieces. It can be perfectly suited for drilling, boring and trepanning through holes, blind and step hole in workpiece: such as, spindle of various kinds of machines, many kinds of hydraulic cylinders and cylinders. It can perform not only drilling and boring, but also rolling and trepanning. The method of the internal-removal (BTA) chip is adopted in drilling, and external metal chips removal is used for boring and trepanning.

-

Hot sale BTA Deep Hole Borehole Machine Tk2120A-2m CNC Horizontal Deep Hole Drilling Machine for Metal Processing

“Quality initial, Honesty as base, Sincere company and mutual profit” is our idea, so that you can create consistently and pursue the excellence for Hot sale BTA Deep Hole Borehole Machine Tk2120A-2m CNC Horizontal Deep Hole Drilling Machine for Metal Processing, The principle of our business is usually to supply high-quality items, skilled services, and truthful communication. Welcome all mates to place trial order for creating a long-term organization connection. “Quality ... -

Massive Selection for High Hardness Carbide Tip Brazed Gun Drill 10 mm Diameter 400 mm Length Metal Drilling Gundrill

This machine is a deep hole processing equipment for drilling cylindrical bar materials. It is a high-efficiency, high-precision and high-automatic machine tool for drilling small holes with external chip removal method (gun drilling method). Through one continuous drilling, the processing quality that can be guaranteed by the general drilling, expanding and reaming procedures can be achieved. The hole diameter accuracy is IT7-IT10, the surface roughness is Ra3.2-0.04μm, and the straightness of the hole center line is ≤0.05mm/100mm.

-

High Quality Automatic Car Wheel Rims Repair CNC Vertical Lathe Vtc75

This machine is a professional product designed according to the needs of motor, valve, water pump, bearing, automobile and other industries. This machine is suitable for rough and finish machining of inner and outer cylindrical surfaces, end faces, grooves, etc. of ferrous metals, non-ferrous metals and some non-metallic parts with high-speed steel and hardware alloy tools.

-

Top Suppliers Large Spindle Bore (CNC) Oil Country (Pipe Threading) Lathe CW6636X4000

This series of machine tools are mainly used for pipe thread processing, and can cut metric and inch cylindrical and conical pipe threads. It is suitable for processing tubing, casing, drill pipe, etc. in petroleum, metallurgy, chemical, hydropower, geology and other departments.

Mated with CNC system, with high control precision and good reliability. The machine tool can also adopt PLC controller, which improves the reliability and control flexibility of the machine tool.

-

Factory Directly supply High Speed Conventional Precision Gap Bed Lathe Machine CS6250c

CNC end face turning lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND, etc), can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

-

Professional China Hole Honing Machine Hm1860z Lapping/Grinding Deep Hole/Guide Sleeve

2MK2125, 2MK2135 and 2MK2150 series CNC deep hole honing machine adopt iron casting bed, is suitable for honing and burnishing cylindrical deep-hole parts, such as various hydraulic cylinders. It can also perform honing and burnishing step holes, and the hole diameter accuracy after honing can reach IT8-IT9, the surface roughness can reach Ra0.2-Ra0.4μm. it can also repair the taper, ellipticity and partial hole tolerance with the partial honing. It can directly perform high efficiency honing of cold drawing steel pipes. This series deep hole honing machine is an ideal machine for deep-hole machining with high accuracy and high efficiency.

-

Wholesale OEM/ODM Japan Manual Engine Speed Lathe (used on ocean ship, drilling machine)

This machine tool is a universal engine concentional lathe, which is suitable for turning outer circle, end face, grooving, cutting, boring, turning inner cone hole, turning thread and other processes of shaft parts, cylindrical and plate parts of different materials with high-speed steel and hard alloy steel tools. The spindle adopts a three-support structure, and the bed adopts an integral bed, so that the bed has high rigidity, and the apron, tool post, and saddle can move quickly. This machine tool has the advantage of strong rigidity, high efficiency, Safe and reliable, easy to operate and beautiful in appearance.

-

Best-Selling Dmtg CDS6166c China Conventional Dalian Lathe Metal Bench Lathe

*4-handles gearbox

*V-way bedways induction hardened and ground;

*Cross and longitudinal interlocking feed, enough safety;

*ASA D4 cam-lock spindle nose;

*Various threads cutting functions available -

OEM/ODM China Three Lines Boring Machine 3 Rows Drilling Machine

T2163 is special equipment for machining deep cylindrical hole of workpieces. It can be perfectly suited for drilling, boring and trepanning through holes, blind and step hole in workpiece: such as, spindle of various kinds of machines, many kinds of hydraulic cylinders and cylinders. It can perform not only drilling and boring, but also rolling and trepanning. The method of the internal-removal (BTA) chip is adopted in drilling, and external metal chips removal is used for boring and trepanning.

-

Wholesale OEM/ODM Complex Deep Hole BTA Drilling and Gundrilling Machine

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Wholesale OEM/ODM Complex Deep Hole BTA Drilling and Gundrilling Machine, Welcome your browsing and any your inquires,sincerely hope we will have chance to cooperate along with you and we can easily build up lengthy well small business romantic relationship with you. Using a complete scientific high quality management program, superi...