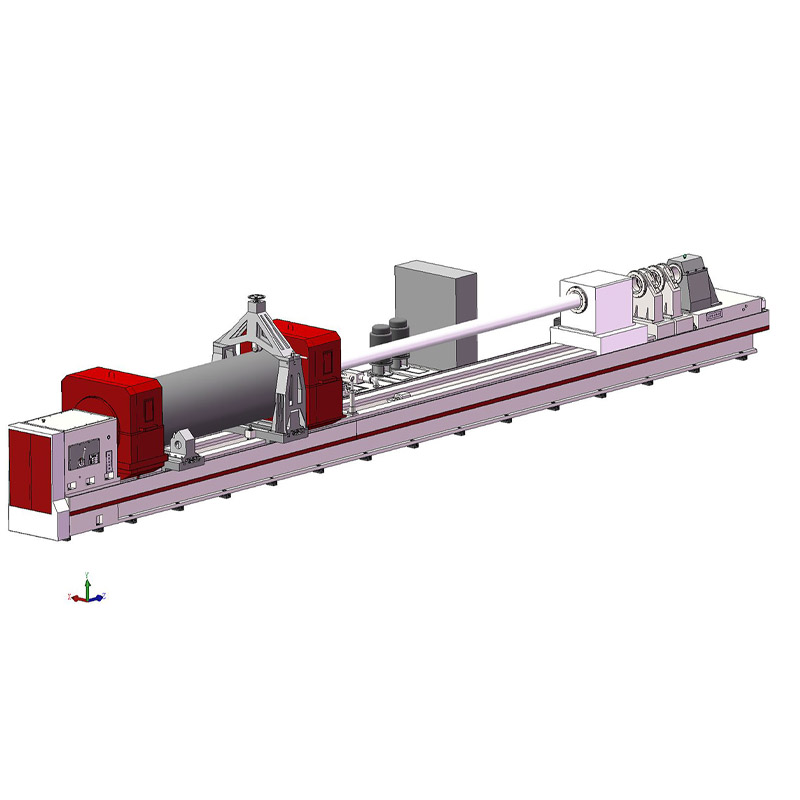

Factory Promotional Metal Cnc Turning - Four guide ways heavy duty horizontal CNC lathe CK61250F series – Premach

Factory Promotional Metal Cnc Turning - Four guide ways heavy duty horizontal CNC lathe CK61250F series – Premach Detail:

Product characteristic

The ck61xxf series is an improved series of heavy-duty horizontal CNC lathes developed by our company based on our long-term experience in horizontal lathe production and adopting internationally advanced design means and manufacturing technology. It implements the latest national accuracy standards and is meticulously designed by integrating electrical, automatic control, hydraulic control, modern mechanical design and other disciplines Mechatronic machine tool products integrating multiple categories of precision manufacturing technology. The structure and performance of the machine tool are applicable. The machine tool has the characteristics of high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

1. It is suitable for cutting tools such as high-speed steel and cemented carbide steel to turn the outer circle, end face, groove, cutting, boring, thread, curved surface and conical surface of shaft, cylinder and disc parts of ferrous metal, non-ferrous metal and some non-metallic materials.

2. The main drive and feed drive adopt a separate structure. The machine tool spindle is equipped with an encoder, and a grating ruler is installed in the Z-axis direction, which can realize full closed-loop control.

3. The bed adopts the separated four guide way structure, and the tool post bed adopts the open hydrostatic guide way.

4. The main drive is driven by the servo motor of the spindle, which is hydraulically variable in two gears to achieve a reasonable speed range of the spindle.

5. The headstock box is of double-layer wall through shaft structure, and adopts double row short cylindrical roller bearings with high-precision adjustable radial clearance. Through optimization design, large spindle straightness and optimal bearing span are adopted to improve the rotation accuracy and dynamic and static stiffness of the spindle.

6. The tool post adopts the vertical blade structure, which can be used for strong cutting, and can be equipped with CAPTO quick change tool interface. The ball screw is used in the transverse direction, and the high-precision rack and double tooth bar clearance elimination structure are used in the longitudinal direction.

7. The tailstock is an integral box structure. The mandrel in the sleeve is a double row short cylindrical roller bearing with high accuracy and adjustable radial clearance. The center is a flange type short taper shank center. The movement of the tailstock uses the worm and worm bus strip technology, which can be clamped and loosened automatically when in place. And is equipped with a hydraulic force measuring device for jacking force.

8. The CNC system adopts Siemens 828D system, and other CNC systems can also be selected by users.

9. According to the user’s requirements, we can provide double tool posts, milling and boring devices, grinding devices, C-axle boxes, etc.

MAIN TECHNICAL

|

specification |

Model |

|||

|

CK61250F |

CK61315F |

CK61350F |

CK61400F |

|

| Max. swing diameter over bed | 2500mm | 3150mm | 3500mm | 4000mm |

| Max. swing diameter over carriage | 2000mm | 2600mm | 2900mm | 3200mm |

| Workpiece length | 6-20mm | |||

| Max. loading weight between centers | 80/100/125t | |||

| Diameter of face plate | 80-150KN.M | |||

| Bed width | 2000mm | 2500mm | 3150mm | 3500mm |

| Front taper of spindle hole | 1150+1250mm | 1500+1600mm | 1500+1600mm | 1850+2000mm |

| Spindle speed range, mechanical two gears, stepless between gears | Short taper flange type, taper: 1:4 | |||

| Longitudinal and transversal feed speed range of tool post | 0.63-125r/Mm | 0.5-100r/Mm | 0.5-100r/Mm | 0.4-80r/Mm |

| Rapid longitudinal and transversal travel speed | 1-500mm/Min | |||

| Taper of quill of tailstock | 3000mm/Min | |||

| Max. travel of quill of tailstock | Short taper flange type, taper: 1:4 | |||

| Main motor power | 200mm | |||

| CNC system | AC125/AC132/AC143/AC160kW | |||

| Max. loading weight between centers | SIEMENS or chosen by buyer | |||

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Factory Promotional Metal Cnc Turning - Four guide ways heavy duty horizontal CNC lathe CK61250F series – Premach , The product will supply to all over the world, such as: Lithuania, Manchester, Iraq, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a people-oriented, meticulous manufacturing, brainstorm, make brilliant company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!