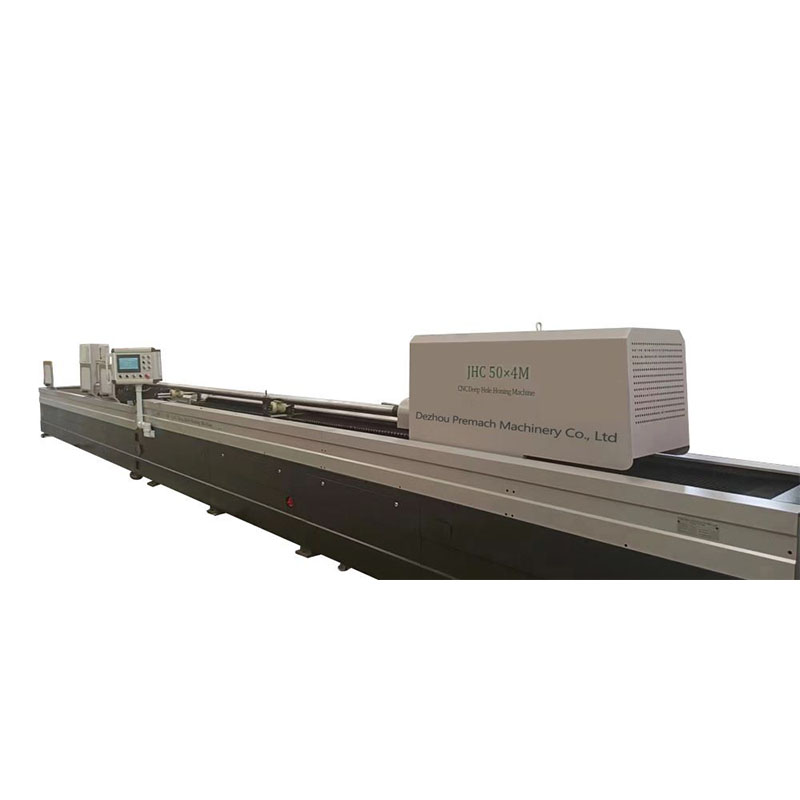

Hones, Deep Hole Honing Machine Jhc Series With Steel Plate Welded Bed

Video Display

Function Description

The grinding workpiece is made of carbon steel and various steels, including the hardened workpiece. If it’s cold drawn steel pipe, it can be directly performed strong honing. This series of deep hole powerful honing machine can process diameter range of 25-1000mm, and can process maximum depth up to 14000mm, which is divided into Jhc10, jhc20, jhc35, jhc50, jhc80, jhc100, etc. the machine is widely used in mold manufacturing, hydraulic machinery, engine industry, aerospace industry, military industry, heat exchanger industry, construction machinery industry, coal machinery industry and other parts of deep hole processing, specially used for various hydraulic cylinders, cylinders and other cylindrical precision deep hole pipe inner wall. It is especially suitable for honing and polishing pipe fittings with stepped holes.

The feature of the deep hole powerful honing machine are as follows:

1. High machining accuracy (≤ 0.02) and high roughness (≤ Ra0.2-0.4).

2. The dimensional accuracy is IT6-IT7, and the honing head is easy and accurate to be adjusted. The honing head is tightened or expanded by the servo motor and speed reducer so as to keep a consistent honing force.

3. The honing length is controlled by the numerical control program, and the machining size is controlled by the number of reciprocating honing.

Technical parameter

|

Name |

Item |

Parameter |

|||||

|

JHC10 |

JHC20 |

JHC35 |

JHC50 |

JHC80 |

JHC100 |

||

|

Working capacity |

Honing Dia. |

Φ30-100mm |

Φ40-200mm |

Φ40-350mm |

Φ40-500mm |

Φ40-800mm |

Φ100-1000mm |

|

Honing depth |

500-6000mm |

500-9000mm |

500-9000mm |

500-12000mm |

500-12000mm |

500-14000mm |

|

|

Max. honing allowance |

0.4-1mm |

0.4-1mm |

0.4-1mm |

0.4-1mm |

0.4-1mm |

0.4-1mm |

|

|

Clamped Dia. range of workpiece |

Ф50mm-Ф250mm |

Ф50mm-Ф350mm |

Ф50mm-Ф500mm |

Ф50mm-Ф700mm |

Ф60mm-Ф1000mm |

Ф70mm-Ф1200mm |

|

|

Spindle of travel head with rotating honing rod |

Center height |

200mm |

300mm |

350mm |

480mm |

700mm |

950mm |

|

Spindle speed |

3-200rpm, stepless |

3-160rpm, stepless |

10-150rpm, stepless |

15-150rpm, stepless |

15-100rpm, stepless |

15-100rpm, stepless |

|

|

Torque of honing rod |

≥500N.m |

≥600N.m |

≥800N.m |

≥1000N.m |

≥1500N.m |

≥2200N.m |

|

|

Reciprocating speed |

1-40m/min, stepless |

1-40m/min, stepless |

1-40m/min, stepless |

1-30m/min, stepless |

1-30m/min, stepless |

1-30m/min, stepless |

|

|

Motor And cooling system |

Motor power of travel head with rotating honing rod |

11 KW(servo motor) |

11 KW(servo motor) |

15 KW(servo motor) |

15 KW(servo motor) |

22 KW(servo motor) |

22 KW(servo motor) |

|

Feed motor power |

4.5KW |

4.5KW |

4.5KW |

4.5KW |

4.5KW |

4.5KW |

|

|

Motor power of cooling pump |

0.45KW |

0.45KW |

0.45KW |

0.75KW |

0.75KW |

0.75KW |

|

|

Flow of cooling pump |

50L/Min. |

50L/Min. |

50L/Min. |

60L/Min. |

60L/Min. |

60L/Min. |

|

|

Capacity of cooling tank |

200L |

200L |

200L |

200L |

300L |

300L |

|

|

Machining accuracy |

Machining accuracy |

IT7-IT8 |

IT7-IT8 |

IT7-IT8 |

IT7-IT8 |

IT7-IT8 |

IT7-IT8 |

|

Machining roughness |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

Ra0.4μm-Ra0.2μm |

|

|

roundness |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

|