China New Product External Thread Cutting On Lathe Machine - Heavy duty horizontal CNC lathe CG series – Premach

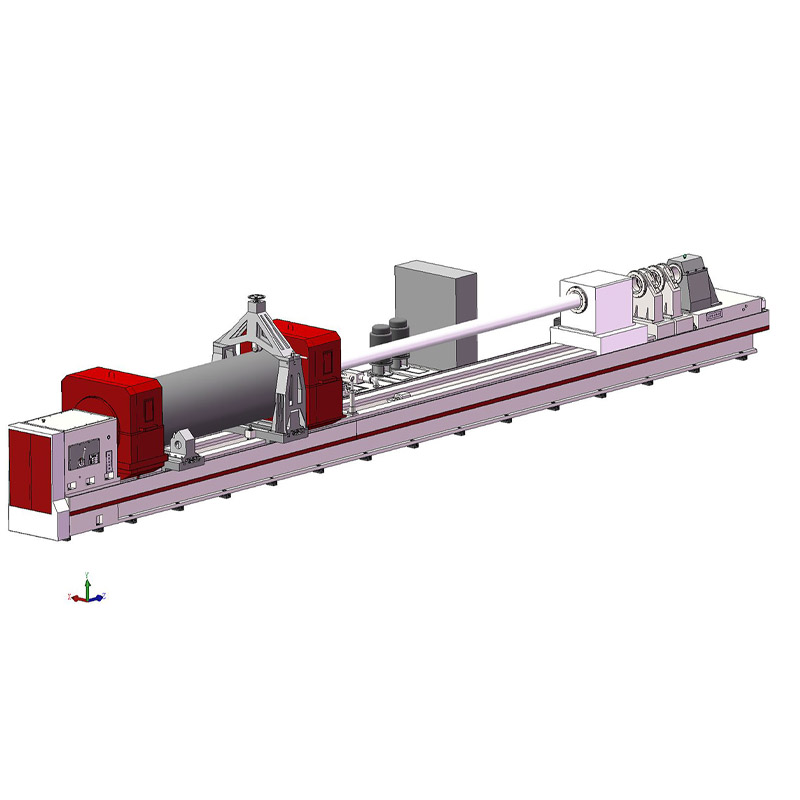

China New Product External Thread Cutting On Lathe Machine - Heavy duty horizontal CNC lathe CG series – Premach Detail:

Product characteristic

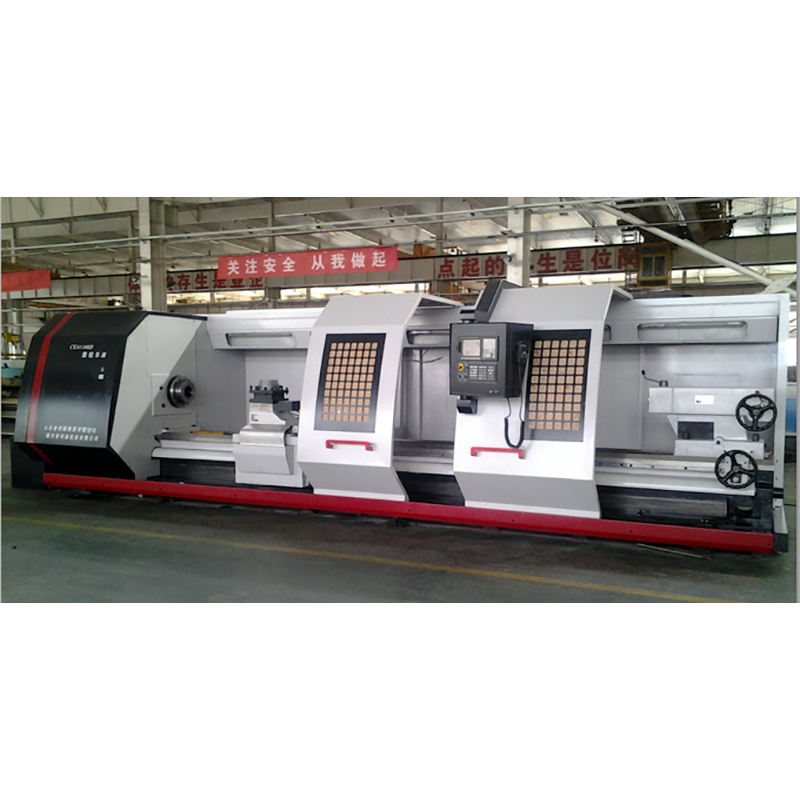

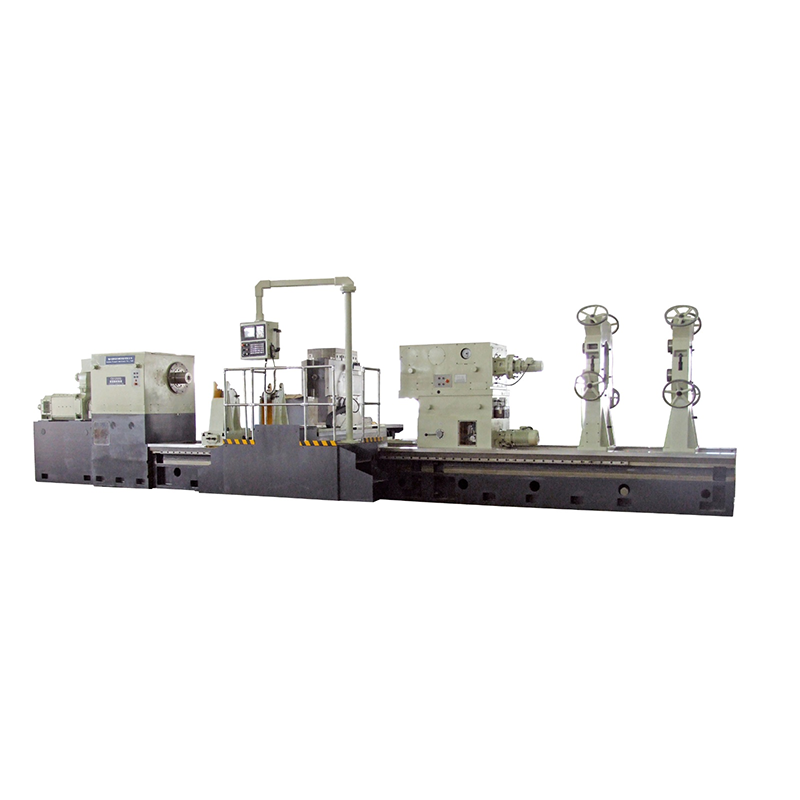

This series of heavy-duty horizontal lathes is a kind of well-designed and multi-disciplinary lathe integrating electrical, automatic control, hydraulic control and modern mechanical design, which is based on the our company’s long-term experience in the production of horizontal lathe. has absorbed the advanced technology of the international era, adopted the international advanced design means and manufacturing technology, such as three-dimensional modeling, simulation design, finite element analysis, etc. Mechatronic machine tool products integrating multiple categories of precision manufacturing technology.

This series of heavy-duty lathe has excellent structural performance. The machine tools are characterized by high dynamic and static stiffness, long service life, high processing efficiency, safe and reliable functions, convenient operation and beautiful appearance.

1. The spindle of the headstock is of through shaft structure. The spindle is supported by high-precision double row cylindrical roller bearings, with has high accuracy and good stability.

2. The main drive is driven by AC spindle servo motor or DC motor, with two mechanical gears, stepless speed regulation within gears, wide speed range and good adaptability.

3. The guide way of the bed adopts the integral three guide way or the integral four guide way, and adopts the precision grinding processing method. The main guide way surface of the bed adopts the medium frequency quenching treatment, and the hardness can reach HRC50.

4. The tailstock is of integral box structure, and the mandrel in the sleeve adopts double row short cylindrical roller bearing with high precision and adjustable radial clearance; The sleeve and tailstock are mobile and equipped with force measuring devices.

5. The tool post adopts ball screw in the transverse direction and high-precision rack and double tooth bar clearance elimination structure in the longitudinal direction, which improves the transmission accuracy of the tool post.

6. The machine is equipped with walking platform and hanging button station, which is convenient for operation.

7. The range and number of open and closed steady rests can be provided according to user requirements.

8. Chinese CNC system is adopted for C61xxc, G and G-I series CNC systems; CK61xxC, G and G-I series adopt Siemens 828D system. Other numerical control systems can also be selected by the user.

9. According to the user’s requirements, we can provide double tool post, milling and boring devices, grinding devices, metal chips conveyors, tool cooling systems, etc.

MAIN TECHNICAL

|

specification |

model |

|||

|

C/CK61125 |

C/CK61160 |

C/CK61200 |

C/CK61250 |

|

| Max. swing Dia. over bed | 1250mm | 1600mm | 2000mm | 2500mm |

| Max. swing diameter over carriage | 1000mm | 1250mm | 1600mm | 2000mm |

| Max. workpiece length | 4-20mm | 4-20mm | 4-20mm | 4-20mm |

| Max. workpiece weight between centers | 32T, 40T, 50T | |||

| Type of guide way | Integrated three guide way or integrated four guide way | |||

| Guide way width | 1615mm | 1615mm | 1850mm | 2050mm |

| Diameter of face plate | 1250mm | 1600mm | 1600mm | 2000mm |

| Spindle speed range | 0.8-160r/Min | 0.8-160r/Min | 0.8-160r/Min | 0.8-160r/Min |

| Gears of spindle speed | Mechanical two gears, stepless between gears | |||

| Quill travel of tailstock | 300mm | |||

| Type of tool post | Frame type tool post, vertical four position electrical tool post, vertical four position manual tool post | |||

| Feed range of tool post | 0.1-1000mm/Min | |||

| Rapid travel speed of tool post | 4000mm/Min | |||

| Step of tool post feed | Stepless | |||

| Main motor power | 75kW/90kW | |||

| CNC system | KND 1000T, SEIMENS 828D or others | |||

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for China New Product External Thread Cutting On Lathe Machine - Heavy duty horizontal CNC lathe CG series – Premach , The product will supply to all over the world, such as: Senegal, Nairobi, Auckland, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We've got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.