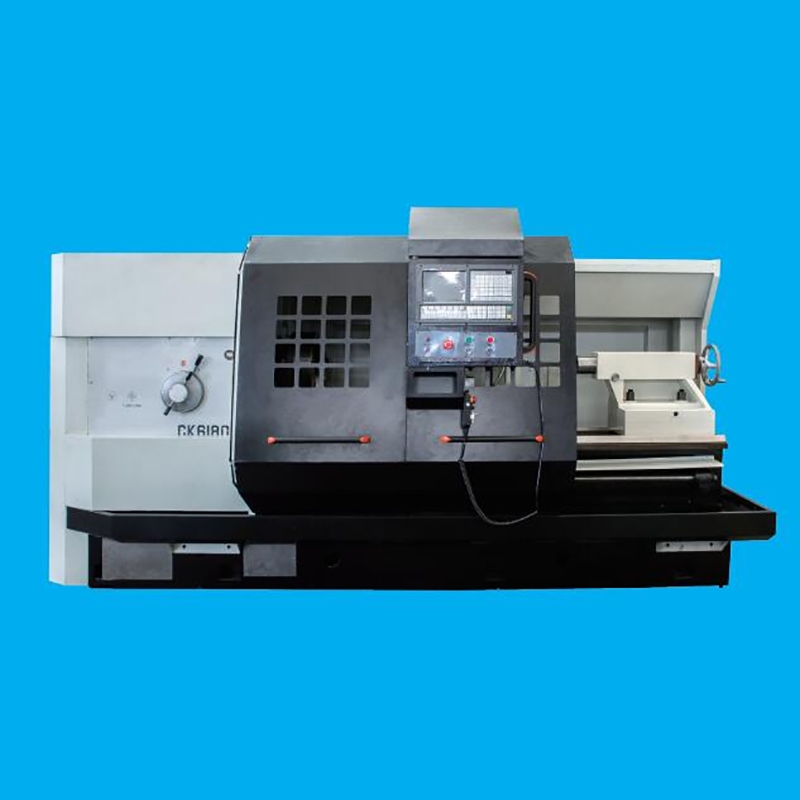

China New Product C Axis In Cnc Machine - CNC horizonta lathe machine CK6163B series – Premach

China New Product C Axis In Cnc Machine - CNC horizonta lathe machine CK6163B series – Premach Detail:

Property of the lathe

Mated with FANUC, SIEMENS or other CNC system, with programmable control and CRTdisplay, linear and circular interpolation. AC servo motor is used for vertical and horizontalfeeding, pulse encoder is used for feedback, and the width of bed guide way is 600mm. The

overall bed guide way is made of high-strength cast iron and ground after ultra-audio frequencyquenching. The guide way of bed saddle is pasted with plastic, and the friction coefficient is small.

The spindle adopts frequency conversion stepless speed regulation and adopts three supports structure with good rigidity.

This CNC lathe is mainly used for turning various kinds of internal holes, external circles, conicalsurfaces, circular arc surfaces and threads, especially for rough and fine machining of small andmedium-sized shaft and disk parts. In the design of the machine, the rigidity of the spindle, the machine body, the bed saddle, the tailstockand other components is reasonably distributed, whichgreatly improves the rigidity of the whole machine and ensures the stability during high-speed

operation and re cutting. Therefore, the machining accuracy of the machine tool can reach IT6-IT7level. As a general-purpose machine, it is especially suitable for efficient and large-scaleprocessing of rotary parts in automobile, motorcycle, electronics, aerospace, military and otherindustries.

The overall layout of the machine tool is compact and reasonable, convenient for maintenance andrepair, and has the characteristics of high accuracy and rigidity. The whole machine adopts a

double sliding door semi protective structure, and has a full-length chip plate at the rear, whichconforms to the principle of ergonomics, is pleasant and easy to operate.

This CNC lathe is specially equipped with an automatic chip conveyer, which is located at the bottom of the rear side of the machine tool to facilitate the centralized recycling of chips.

MAIN TECHNICAL

|

MODEL |

||||

| ITEM | CK6163B | CK6180B | CK61100B | CK61120B |

| Max. swing over bed | 630mm | 800mm | 1000mm | 1200mm |

| Max. swing over cross slide | 300mm | 470mm | 670mm | 830mm |

| Distance between centers |

1500mm 2000mm 3000mm 4000mm |

|||

| Spindle hole |

105mm |

|||

| Max. moving distance of tool post |

|

|||

| longitudinal |

1500mm 2000mm 3000mm 4000mm |

|||

| transversal |

420mm |

520mm |

||

| Spindle speed (number) | 6-20, 18-70, 70-245, 225-750, 4 gears stepless speed | |||

| Main motor power | 11 or 15KW, frequency converting motor | |||

| Rapid travel speed | ||||

| longitudinal |

6m/min |

|||

| transversal |

4m/min |

|||

| Feed resolution ratio | ||||

| longitudinal |

0.01mm |

|||

| transversal |

0.005mm |

|||

| Position number of tool post |

4, 6 or 8, optional |

|||

| Positioning accuracy | ||||

| longitudinal |

0.04/1000mm |

|||

| transversal |

0.03mm |

|||

| Repeat positioning accuracy |

|

|||

| longitudinal |

0.016/1000mm |

|||

| transversal |

0.012mm |

|||

| Repeat positioning accuracy of tool pot |

0.005mm |

|||

| Net weight |

|

|||

| Distance between centers:1500mm |

4300kg |

4500kg |

4700kg |

4900kg |

| 2000mm |

4800kg |

5000kg |

5200kg |

5400kg |

| Overall dimension (LxWxH) |

|

|||

| Distance between centers: 1500mm |

3460x1830x1730mm |

3460x1910x1960mm |

||

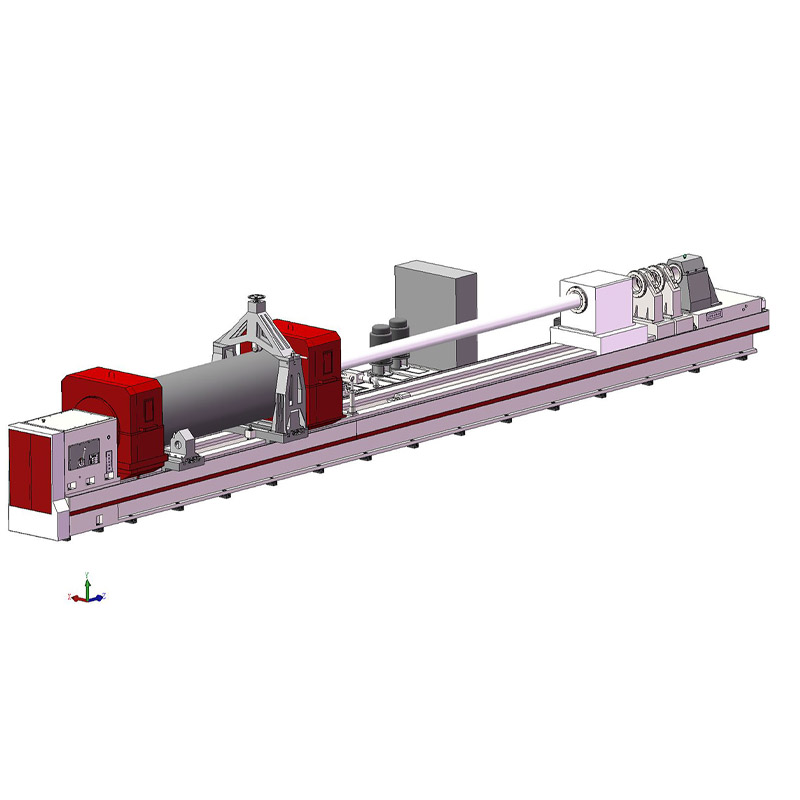

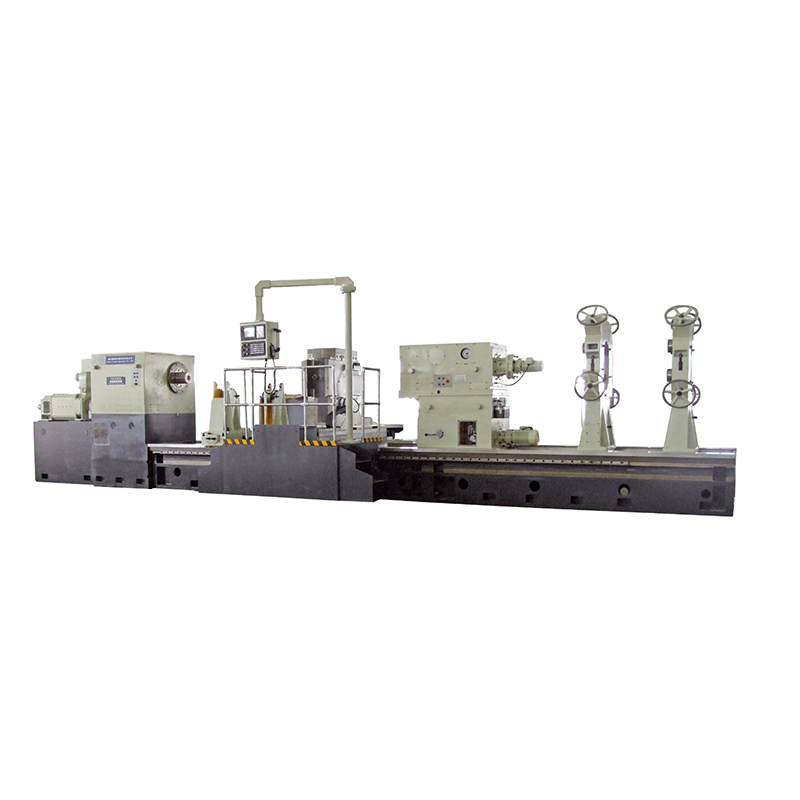

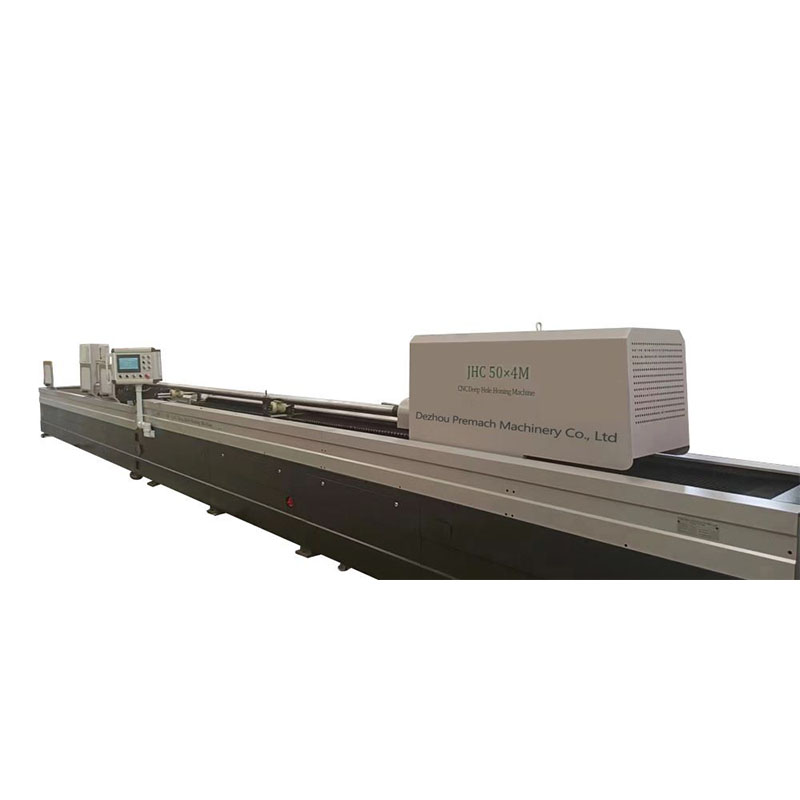

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with China New Product C Axis In Cnc Machine - CNC horizonta lathe machine CK6163B series – Premach , The product will supply to all over the world, such as: UK, Israel, Uganda, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.