High Straightness ± 0.05/2125mm Requirement Of The Boring Hole

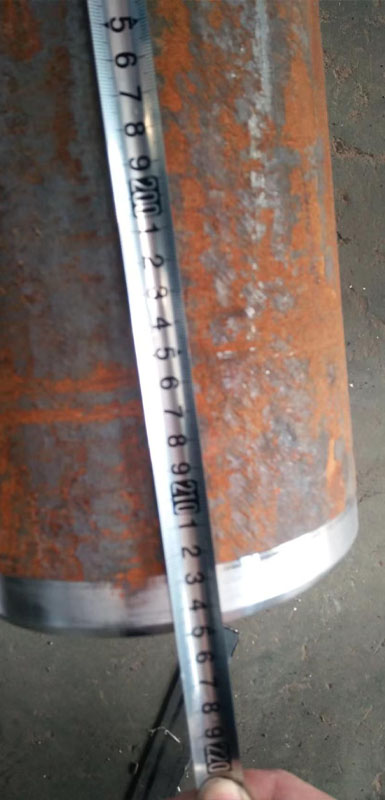

In December 2019, a S. Korean customer inquired about a deep hole drilling and boring machine, requiring that the diameter of the drilling hole is 90mm, and the diameter of the hole after finish boring is 97.5mm. And the workpiece length is 2125mm. However, the requirement of straightness of the inner hole after processing is very high, it must reach ± 0.05 on the total length. The customer does not accept the honing process. According to the customer's requirements of high straightness, we suggest to prepare two workpieces with 45# steel material according to the customer's requirements, and state that the workpieces need heat treatment after drilling to ensure the straightness after boring. Because the drilling and heat treatment takes a long time, we ask the customer to come to our company to check the machining accuracy and detect the final straightness during the last two processes of semi-finish boring and finish boring. It is suggested that the testing method for straightness of the hole after machining is making a standard test stick with 500mm length, which was ground its outside surface up to the standard of straightness, and the O.D. of this standard testing stick is 97.43mm, if this standard stick can pass through the hole smoothly, it means that the hole accuracy reach requirement, and the customer accepts this measure. Finally, after the test parts were processed by our deep hole drilling and boring machineT2120 / 3000mm, the straightness accuracy was qualified. The customer successfully ordered the machine and delivered it in May 2020.