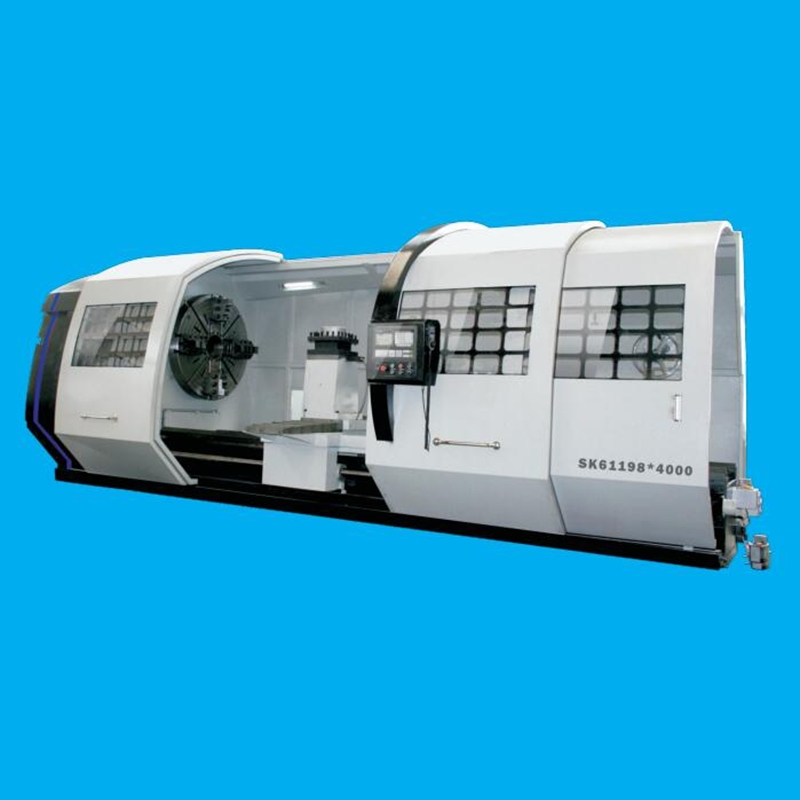

Best-Selling Flat Bed Cnc Lathe - CNC horizontal lathe machine SK61128 series – Premach

Best-Selling Flat Bed Cnc Lathe - CNC horizontal lathe machine SK61128 series – Premach Detail:

Property of the lathe

Mated with FANUC, SIEMENS or other CNC system, with programmable control and CR display. AC servo motor is used for longitudinal and transversal feeding, pulse encoder is used for feedback.

There are four kinds of main drive of turning for different model: manual 21 kinds with 3.15- 315r/min, 2.5-250(21)r/min, 2-200r/min and four stepless speed change driven by servo spindle motor, which increases the constant power range. Two linkage control axes, Z axis and X axis, use ball screw pairs and AC servo motors to achieve longitudinal and lateral movement. The semi closed loop control has good positioning accuracy and repetitive positioning accuracy.

Wide cutting range, can process outer circle, inner hole and end face. Grooving, processing conical surface, chamfering, conical or cylindrical thread and arc surface.

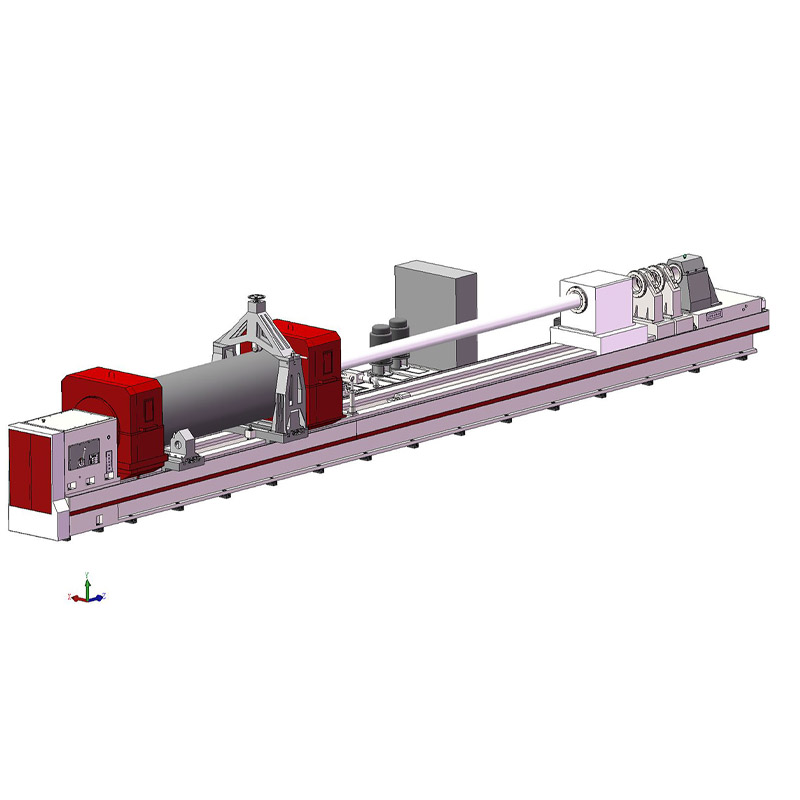

The bed surface of the machine is of Flat-V structure. It is iron cast with high-strength resin sand.

The bed surface is subject to medium frequency quenching treatment. The hardness is HRC50.

The quenching depth is deep, which is conducive to the second regrinding of the machine tool.

The machine body has strong rigidity, large bearing capacity and good stability. The carriage is treated by sticking plastic (polytetrafluoroethylene soft belt). Because the polytetrafluoroethylene material contains lubricating elements, the difference between the dynamic and static friction coefficients are small, which greatly reduces the friction between the drag plate and the guide way surface of the bed and prevents creeping. The machine bed is cast with an arch gate for backward chip removal, and the chips are directly discharged to the chip receiving tray, which is convenient for chip removal and cleaning.

MAIN TECHNICAL

|

MODEL |

|||||

| ITEM | SK61128 | SK61148 | SK61168 | SK61198 | SK61208 |

| Max. swing over bed | 1280mm | 1480mm | 1680mm | 1980mm | 2080mm |

| Max. swing over cross slide | 840mm | 1040mm | 1240mm | 1540mm | 1640mm |

| Distance between centers |

2000mm-16000mm |

||||

| Bed width |

1100mm |

||||

| Spindle hole |

Φ130mm |

||||

| Diameter of quill of tailstock |

Φ260mm (with built-in small spindle) |

||||

| Max. loading weight of workpiece |

10000kg |

||||

| Max. moving distance of tool post |

|

||||

| longitudinal |

Distance between centers minus 600mm |

||||

| transversal |

800mm |

||||

| Spindle speed (number) | 3.15-315r/min, or 2.5-250(21)r/min, or 2-200r/min | ||||

| 4 gears, frequency converting driven, 5-20,15-60, 25-100, 65-250 | |||||

| Main motor power |

30KW |

||||

| Rapid travel speed | |||||

| longitudinal |

4m/min |

||||

| transversal |

3m/min |

||||

| Position number of tool post |

4, 6 or 8, optional |

||||

| Positioning accuracy | |||||

| longitudinal |

0.05mm |

||||

| transversal |

0.03mm |

||||

| Repeat positioning accuracy |

|

||||

| longitudinal |

0.025 |

||||

| transversal |

0.012mm |

||||

| Repeat positioning accuracy of tool pot |

0.005mm |

||||

| Net weight |

|

||||

| SK61168x4000mm |

22000kg |

||||

| Overall dimension (LxWxH) |

|

||||

| SK61168x4000mm |

7300x3000x2500mm |

||||

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Best-Selling Flat Bed Cnc Lathe - CNC horizontal lathe machine SK61128 series – Premach , The product will supply to all over the world, such as: Norway, Provence, Czech republic, If you are interested in any of our products and solutions or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.